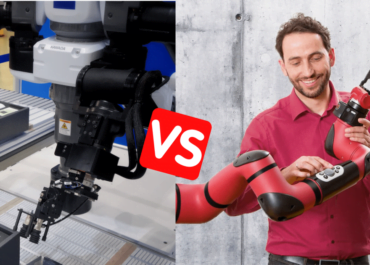

In the 2010s, a few pioneering robotics companies sought to introduce small and medium-sized industries to automation. They invented lightweight and safe robots that can work alongside workers – collaborative robots

Since then, many actors have rushed into this fast-growing market and brought differentiating cobotic models. But what are the most iconic examples of cobots?

Here are the most popular and best-selling cobot series on the market, and the reasons for their success. Let’s take a look!

The Universal Robot series

Founded by 4 Danish students, Universal Robot is one of the most iconic companies in cobotics. They worked on the first cobot prototypes back in the 2000s, and released their first cobot, the UR5, in 2008.

Since then, they have greatly expanded their range of UR models to fit many applications. This has allowed them to become the most popular cobot series in the world, owning nearly half of the market share.

The UR series’ recipe for success? A space-saving design and a user-friendly interface. UR robots are lightweight and agile, making them suitable for a wide range of applications. They have safety features that allow them to collaborate with workers. Universal Robot has also make sure anyone can program them, thanks to an easy-to-use interface and hand-guiding features.

Even today, with their augmented e-series model, they offer unbeatable versatility and user experience.

KUKA LBR models

UR is not the only company that has pioneered the industry. When the German Aerospace Center worked on a lightweight and self-carrying robot, automation manufacturer Kuka was impressed by the prototype.

The company thus decided to buy the license in 2004 and market a refined version of the model under the name KUKA LBR. The advanced model, the Kuka LBR iiwa, has become a landmark for major industries, including automotive.

Why so much success?

The great selling point of these robots is that they are equipped with advanced force and position sensors. Thanks to great accuracy and agility, they automate redundant industrial applications, such as assembly, pick-and-place and machine loading.

With their lightweight and sensitive design, they can also work alongside workers without risk. This has given them a competitive advantage in labor-starved industries.

And that’s why Kuka continues to gradually expand its market share.

Fanuc CRs

Building on their longstanding expertise in industrial robotics, FANUC launched their own cobot models in 2015, under the CR series. To enable their customers to automate a wide range of applications, they have gradually expanded their series (through augmented reach and payload capabilities).

The CR series is mostly popular for its versatility, reliability, and customization. Fanuc cobots feature high-motion repeatability and robust materials. They also support many FANUC accessories, including grippers, screwdrivers, vision, or force control devices.

This, combined with their outstanding performance, allows them to be productive in many industrial applications.

TM-Omron cobots

Techman Robot launched its TM cobot series in 2016, and has become one of the most innovative on the market.

The success of TM cobots mainly relies on advanced sensory technology. They are among the first cobots featuring computer vision, which allows them to manipulate objects in a very flexible way.

The TM series also provides accurate force and torque sensors that prevent collisions with workers. Combined with a user-friendly interface, the TMS cobots handle complex applications with great efficiency.

Such success has led the industrial distributors Ormon Group to help Techman expand its market share. That’s why Ormon’s TM cobots are finding great success in Korean and European industries.

ABB Yumi

ABB is an automation company with big ambitions for the cobotics market. With the launch of their Yumi series in 2015, they created the first collaborative robot with two arms. Expanding their series little by little, ABB wanted to bet on the precision and safety of these cobots.

As a result, Yumi cobots provide advanced force and collision sensors that solely ensure workers’ safety. The Yumi’s grip is also very precise, allowing it to handle small objects at high speeds. This means they can work close to employees in changing and flexible applications, such as small part assembly.

With this series, ABB has helped many industrial, food, and pharmaceutical companies to make their production cycles more flexible. With their latest SWIFTI and GoFA models, the group has further expanded its cobot range, focusing on speed and user experience.

So these are the cobot models of choice for any company that wants human-machine automation!

Sawyer from Rethink Robotics

Rethink Robotics was founded in 2008 by two robotics enthusiasts that aimed to improve human-robot interaction.

In 2015, they designed a user-friendly robot model, Sawyer, to add a human touch to industrial processes. Sawyer immediately stands out for its pleasant and human-like design. It provides an interface that maintains eye contact with the worker and expresses emotions. At the same time, it has force sensors that ensure optimal safety. All this helps improve the acceptability of automation among workers.

But Sawyer has other major assets. It has external cameras and intelligent vision software that allows great industrial flexibility. Combined with its compact design, this means it can be deployed on fairly complex and narrow applications.

Since its acquisition by the German HAHN Group, the Saywer series offers improved capabilities and promises new updates to come !

Aubo I-series

Aubo is a Chinese startup that has built on years of development and research to design remarkable cobot models. They launched their Aubo I-series in 2016 to conquer not only the Asian market, but also the American market.

The specificities of Aubo I robots lie in their versatility and modularity. The cobot’s components can be easily disassembled and reassembled, and they can be adapted to many applications. The programming system is also open to many coding languages and accessories. Any user can install an API or code a new protocol for the cobot.

Aubo also provides a very ergonomic interface, to make automation accessible to any worker. Its manual controls and 3D simulator offer many application possibilities.

Since its first model, Aubo has greatly extended its range, from the Aubot i-3 to the Aubot i-16. The company has been very successful in meeting the different needs and production demands of American and Chinese companies.

Panda by Franka Emika

Sami Haddadin, a robotics specialist at the University of Munich, founded Franka Emika in 2016 with one goal in mind: to make robotics accessible to everyone. In 2017, he and his team introduced Franka Emika Panda, a cobot aimed at accelerating research around human/machine collaboration.

As an experimental cobot, Panda has a remarkable user experience and technical performance. Besides sensitive 7 axes, it provides one of the most intuitive programming interfaces on the market.

It can especially leverage an open-source software ecosystem. On the Franka World cloud platform, users can share and find new custom applications. They can immediately access programming resources, and test their cobot on innovative applications.

Because of this, it has attracted many universities and research institutions. No doubt that Panda will bring many innovations in this field!

Dobot Magician

Taking a different approach from the market, the cobots from Chinese company Dobot focus on small-scale designs. Their Dobot Magician range is aimed at small businesses, workshops and studios, and even B2C.

Equipped with all kinds of accessories, these desktop cobots have features like 3D printing, laser engraving and drawing. Originally intended for education, they are now aimed at craftsmen and artists who seek to automate their work processes. They have a user-friendly visual interface and an open software environment to find new original applications.

The Dobot Magician series has opened up a new customer segment in the market, helping individual makers to express their creativity. It is now gradually expanding to education for children and small industries by focusing on safety and creativity.

OTTO cobots

Cobots can also be mobile, and OttoMotors knows it more than anyone. With its OTTO series, this company wants to automate material transportation in companies.

OTTO autonomous robotic vehicles stand out for their ability to move in tune with workers and other cobots. The different models adapt to the types of materials to be transported (pallets, parts, packaging…) and can also act as a conveyor on production lines. The ergonomic Fleet Manager interface also provides traffic data to optimize your fleet processes.

For all these reasons, OTTO is one of the leaders in this emerging market of mobile cobots.

That’s it, you now know what cobots look like! And if you want a deeper comparison between these robots, check out our guide.