Dispensing, pouring, and filling up liquids all day can be a long and tedious job.

Workers need to precisely apply the liquid on different surfaces and containers, while evenly dosing every part.

That’s why robots have become a great alternative to speed up dispensing processes and enable output consistency. Collaborative Robots are especially a good fit for low-volume high-mix industries, as they are very flexible and can adapt to small batches.

But which cobot to choose from, and with which robotic dispenser attached?

Here’s our full guide about robotic dispensing implementation.

Why use Robots for Dispensing and Gluing Tasks?

Whether sealing, gluing, or filling in containers, dispensing is not an easy task for average workers. They need a great deal of skill, while ensure to apply the right amount of liquid in the right place. So it’s rarely the favorite task among industrial workers.

No wonder then that various industrial robots and industrial systems have been invented to automate these repetitive and unrewarding processes.

Yet, while they feature great accuracy and deliver a very good output rate, they take time to program and set them up on new production settings. They are only viable in high-volume, low-mixed industries.

This is where collaborative robots stand out, as they are easy and quick to deploy, program, and redeploy. You can save a lot of time, while easily switching from one task to another.

So you can expect many benefits from dispensing and gluing cobots :

- Better output quality, consistency, and minimum waste

- Improved cycle times and throughput: cobots are faster than human workers

- High flexibility and easy redeployment: you can switch quickly from one program to another between tasks.

- Space-saving specs and high safety features

Does this relate to you?

The Best Dispensing Robots: our Curated List

With their incredible agility and dexterity, more and more cobot models are enabling dispensing applications. Here are the latest cobotic models that can skillfully handle and apply liquids on your part surfaces :

Universal Robot

There’s a good chance you’ve heard of Universal Robot. The danish forward-thinking company is dominating the industry with very versatile and high-performance cobot models. The UR cobot range from space-saving and lightweight to long-range and high-payload models. The UR + ecosystem especially supports a wide range of end-effectors. That’s why they are always a good choice to automate such a specific application as dispensing.

Eva from Automata

Automata is a company that aims to automate laboratory and pharmaceutical applications. To help with that, they have introduced their robotic model Eva to handle plate placements and liquid handling on lab cells. With compact and lightweight design, Eva can fit anywhere in your research and production workshop, and will precisely and evenly dispense liquids over your workpieces.

Kassow

Kassow is a newcomer in the cobotic industry, with differentiating specs and features. Kassow offers unique 7-axis robot models showing high-range and accurate capabilities. That makes them particularly good at reaching and accurately covering your parts with liquids. On top of that, they are supporting market-leading AimRobotic dispensing tools. So you might definitely check them out.

Dobot

Dobot is a Chinese company that provides modular and game-changing cobot models. They are known for small-scale cobots like Dobot Magician which helps automate drawing, painting, and gluing household applications. But Dobot has also launched industrial cobots : the CR Dobot Series. As it can leverage an ever-growing partner and accessories ecosystem, it is an ideal solution for dispensing applications. It also demonstrates good accuracy, ease of use, and flexibility to automate those tasks.

What are the Best Robot Dispensers?

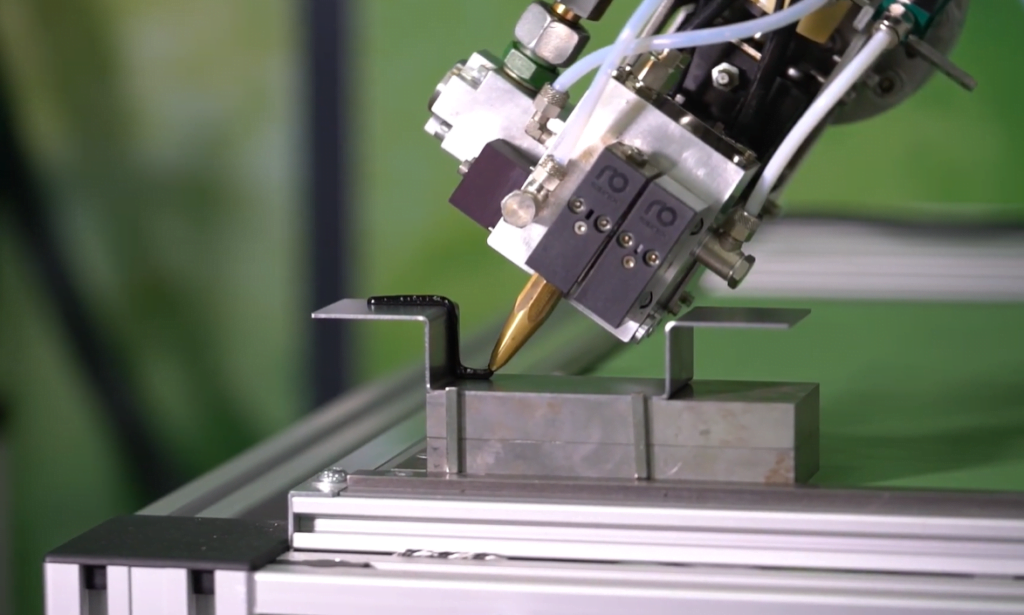

Syringes, cartridges and any other dispensing tool are not only made for human hands. They fit perfectly well on robotic arms. And many manufacturers are selling quality robotic dispensing kits to automate your sealing, greasing, and gluing applications :

Aim Robotics

AimRobotics is making its mark on the market with highly-innovative dispensing tools. Their SD and FD dispenser series are specially made for precise collaborative robot applications. Electrically powered, they show one of the best repeatability on the market to accurately pour liquids on your parts. Their calibration software also makes them instantly deployable and ready-to-use. They natively support Universal Robot models, but can also connect to any collaborative robots.

Robatech

Robatech has designed a 360° collaborative robot gluing kit to deal with any geometrically irregular part. The adhesive application system is very versatile and can apply adhesives or sealants in dot, curl patterns or even wild spraying. The integration kit works mainly with UR and FANUC cobot, but can connect to accessories like various filling systems and rotary unions.

Fancort

Fancort Industries provides an all-in-one UR+ Dispensing kit to quicly get started. You’ll get the syringe, controller, cables and mounts to easily set up a dispensing system on your UR cobot. Pneumatically-driven, the syringe needs minimal integration to run on your collaborative robot.

Robot27

Robot27 provides a wide range of robotic dispensing heads for collaborative applications. Whether syringe, cartridge, two-part, SEMCO cartridge, you can find the best pneumatically-driven tool and mounting settings to set up your application. These standard dispensing tools are compatible with UR robots and will help you flexibly automate your gluing and sealing tasks.

How to automate your Dispensing Applications: a Step-by-Step Guide

Setting up a new dispensing and gluing application can bring significant changes to your work organization. That’s why you need to carefully consider the new working cell, the human-robot interactions at hand, and your employee’s training.

That can take a lot of consideration, so you might as well follow this step-by-step collaborative dispensing and gluing implementation process :

1. Figure out your needs

First things first, you need to agree on the goals you want to achieve through your dispensing automation project.

What’s your main issue? Reducing waste, having more flexibility and a faster set-up to handle small batches of various shapes, improving throughput and cycle times, or freeing up your workers from tedious and repetitive tasks?

When you know what you’re aiming for, you have everything in your hands to make the right buying decision.

2. Opt for the right dispensing tools

Depending on your requirements, you can look for specific features to choose the best dispensing tool :

- Technical specs: repeatability is a must to ensure your robot can accurately and evenly spray liquid on your workpieces. Speed and reach are a plus to get better performance and a shorter turnaround time.

- User-friendliness: is the robot coding interface easy to learn and use for your dispensing workers?

- Safety: which features ensure your worker’s protection against splashes and unexpected collisions?

- Flexibility: is your robot lightweight, quick to teach and reprogram on new parts? This will greatly matter if you’re dealing with part series of various shapes.

3. Consider your Employee’s safety

Even though cobots are technically safe, you still need to do a safety assessment of your sanding cell. It’s your job to make sure that your robots’ collaborative features are in good use and that they don’t pose any threat to your workers.

For dispensing applications, the danger might mainly come from heated or corrosive liquids, but it also can happen between the robot arm and the workers. So you need to consider every interaction between your robot, your workers, your material, your end-effectors, and your parts.

4. Redesign your working cell

Implementing a robot always implies a new work configuration. As you don’t have to add fences, cobots free up more space for your working cell. You might as well facilitate your workers’ movements, while keeping your robot on a dedicated mounting setting. That way, your workers can easily come check your robot’s work and get back to other priorities.

5. Rethink your work organization

Dispensing robots are not just one more addition to your sanding process; they completely redefine your worker’s roles and tasks. As they continuously work on your application, who will supervise it, and what will dispensing workers do? Will they monitor its work, focus on sophisticated dispensing applications, or handle other tasks?

We recommend leveraging human-machine collaboration – where robots continuously operate and workers monitor their work and are ready to intervene in any unexpected situation so that you get the best of both.

6. Manage your Employees’ Training

Finally, you need to organize your employee’s training. Even though collaborative robots are often easy-to-use devices, they still need to know how it works and how they can handle them. The training should particularly emphasize coding features and safety protocols. This will make sure employees are confident in their new robotic job.

That’s it, you now know how to set up a flexible and fast dispensing robotic application. Your turn to leverage human and robot combined capabilities and make it stick!