What is the story behind Sawyer from Rethink Robotics?

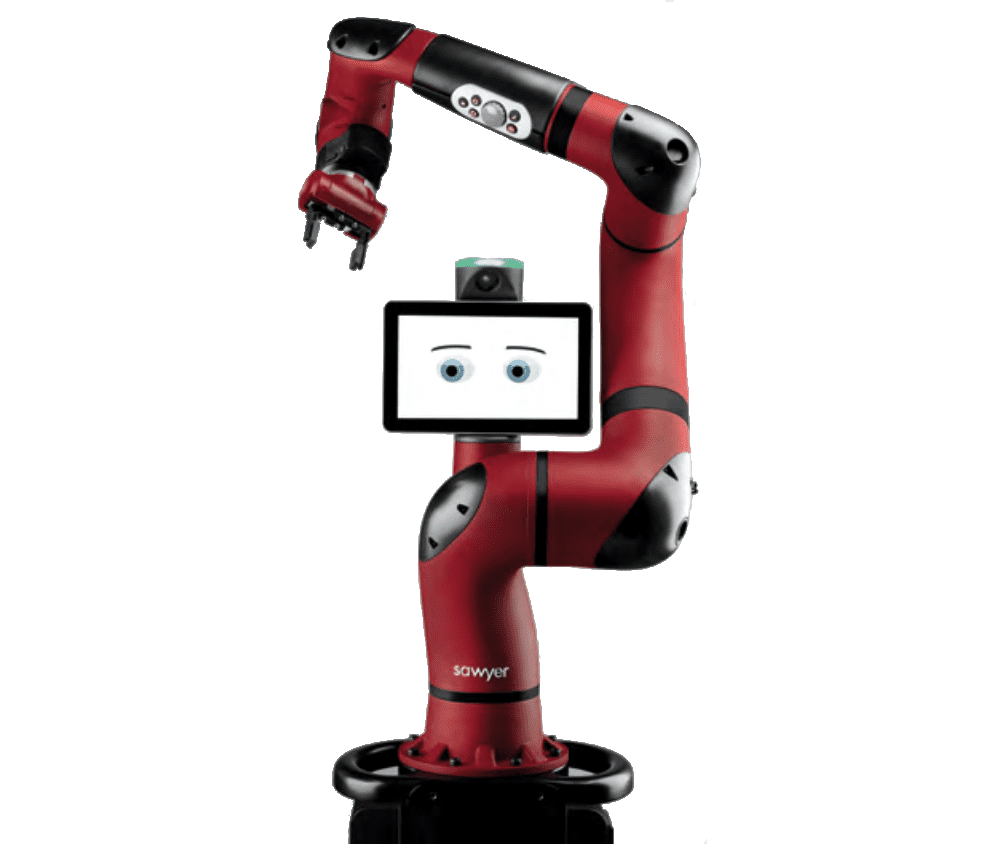

Rethink Robotics is a company founded in 2008 by two robotics enthusiasts, Rodney Brooks and Ann Whitaker. They wanted to tackle the challenge of creating low-cost robots for small businesses. With their robot Baxter in 2012, they entered the collaborative robot market with a more human approach. Their robot had a friendly face, which made it more endearing and acceptable to factory workers. On top of that, it was made with cost-optimized engineering to make it accessible to small and medium-sized businesses.

Since 2015, Baxter’s improved version, Sawyer, has been able to handle smaller, more precise tasks like circuit testing and machine assembly with more sophisticated arms and grapples. The ambition of Rethink Robotics, now acquired in 2018 by Hahn Group, is to make a robot with precise movement and easy-to-use accessible for manufacturers.

And that seems to be accomplished with a flexible, easy-to-handle robot. But let’s see how it really fares today.

How does the Sawyer cobot work?

The first step is setting up and assembling Sawyer. With the cobot arm, you’ll find in the cardboard box its fixation support and the computer controller. After installing it on its device and connecting it with its controller and power, Sawyer’s interface turns on. You can then start to create a task on the interface using the controls located on the arm. With a wide variety of customizable grapples, Sawyer can grab and carry many shapes and materials. He can also carry multiple objects at once.

Once you’ve chosen the right equipment, simply hold down the sensitive part of the arm to activate the zero gravity mode. You can then move the arm in 7 degrees of freedom and repeat each task step by step. For more precise applications, you can use the nudges on the arm to change the angle of the movement in 6 degrees of freedom. You can also customize the working path. All this is done through the graphic interface to memorize and confirm the task.

When you have finished defining the gesture, you can follow and check the work process visually described. When you are satisfied, you can finally launch and test the task, to see if Sawyer performs well.

What are the possible applications with Sawyer?

Sawyer can perform many tasks that require precision movement and may be dangerous or redundant for human workers. Such as:

- CNC machining

- PCB and ICT handling

- Metal fabrication

- Molding operations

- Packaging

- Line loading and unloading

- Testing and inspection

What does the interaction with Sawyer actually look like?

Throughout the interaction with Sawyer, the process is relatively smooth. Once the human worker has set up the robot in a well-defined workspace, he or she can define the angle, position, and movement of the robot with great ease.

However, you need to be familiar with Sawyer’s operation and interface to make it handle more precise objects or perform more detailed maneuvers (welding, metal fabrication, etc.).

The work process involves the use of many buttons on the arm or the interface, which can require great agility. However, the benefit of Sawyer is that workers don’t need to know a single line of code to make it do a efficient job.

The Intera interface allows to code the task visually and is relatively easy to use. The Intera Studio software allows for even more detailed customization, including adding vision functions (for pick-and-place, for example) or making the process more variable and intelligent. This last interface is dedicated to expert workers, who know code functioning (even without using code).

Concerning safety features, Sawyer quickly senses undesired interactions thanks to its motion sensor. You can also easily stop or resume work by giving a slight pressure on its arm. Coupled with its human-like interface, it brings a friendly touch to the robot/human interaction.

Our Ratings

Overall

-

Performance

-

Usabillity

-

Safety

-

Versatility

What to make of Sawyer Cobots ?

All in all, Sawyer Robots are good automation solutions for redundant but precise tasks in small and medium-sized factories. With friendly design, good collaborative features, and reliable vision computing, they can handle demanding applications. But their user interface and technical build can seem quite outdated compared to the latest cobot models on the market. The Black Edition lately released might just change that.