What is the story behind Doosan cobots?

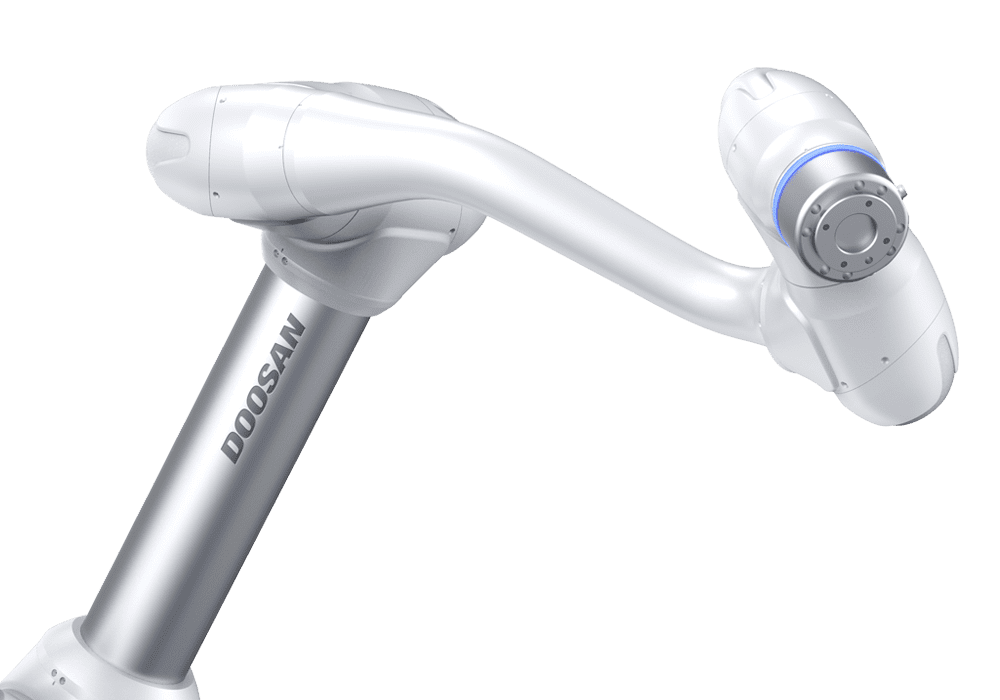

A subsidiary of the Korean heavy industrial and construction group, Doosan Robotics is a new player in the market with ambitious plans. Founded in 2015 to speed up the digital transformation of industries, the company has built up a strong R&D culture to provide cobots of excellence.

Their first models, from the M series, were launched in 2017, showing a deep knowledge of industrial standards. They stood out for their high safety (with torque sensors on their 6 axes allowing advanced collision detection) and dexterity of movement. Doosan has also developed a highly praised user interface and experience.

In 2019, they launched their A and H series in addition to their M series, which demonstrate very high performance and accuracy. These new series are capable of adapting to demanding and intense production needs.

This is also the case with the M series, which is intended to help Doosan target and appeal to the large Korean and European markets. Can they succeed?

How to use Doosan M cobot?

The first step is to set up the robot’s base, the learning interface and the various power cables. You need then to define the cobot’s safety workspace and tune its arms. When turning on the user interface, you can then set up the safety features (emergency stop button), activate the cobot’s servo, and define the home position.

To code the cobot tasks, users can write the different steps in the Task Builder tab. After defining the inputs and outputs of the right end-effector, they can add different motion and action blocks to define the task at hand.

The robot movement can work in 3 ways. The Jog mode makes the cobotic arm move along its rotation axes from one point to another. Move mode moves the cobot through specific positions. Set mode moves the cobot along a designated line or plane.

To set these positions, the user can either define the parameters manually or use the Cockpit mode to move the robot arm freely. Thanks to the buttons on the arm, the free control mode is a very intuitive way to teach the robot.

When workers have finished programming, they can use the task simulator or turn on the real mode to check the work-in-process.

The program will then return various error messages to correct. After several trials and debugging, the user can finally save and run his program according to a defined number of cycles, speed and duration.

What are the applications of the Doosan M-Series?

A powerful cobot, Doosan can perform both traditional and specialized applications very well:

- Pick & Place

- Welding

- Dispensing and painting

- Machine loading

- Packaging and inventory management

- Screwing

- Quality inspection

- etc.

What about the interaction with Doosan M series?

It’s safe to say that interacting with Doosan M series is a very smooth and well-thought-out experience. In several aspects :

First, the cobot is equipped with the latest safety features. It provides workspace safety features for tailored interaction and automatically stops when it detects a collision.

Second, the Doosan cobot interface offers one of the best user experiences on the market. The control interface menus are intuitive, and it is easy for users to program-specific tasks. The software also provides smart recommendations for workers to optimize their process. This means that any employee can take control of a process and automate it with little practice.

The standard quality end effectors (such as the gripper or the screwdriver) are efficient production tools to handle industrial applications. Doosan also provides an intelligent vision accessory. However, this requires more specialized skills.

Finally, thanks to high performance, the cobot is a reliable support for industries with demanding production standards. Doosan models have some of the best technical characteristics on the market (payload, precision, range, speed). Their torque sensors can also handle more accurate applications (welding, screwing, distribution…).

Our Ratings

Overall

-

Performance

-

Usabillity

-

Safety

-

Versatility

What to make of Doosan M-Series ?

All-in-one, the Doosan Ms undoubtedly provides among the most innovative cobot models on the market. Besides brilliant design and technologies, they are fast and reliable tools to handle for workers. They can also assist them in more sophisticated applications, but you might then need higher technical skills.