The cobotics market is relatively new, finding its birth in the 2010s.

However, many companies and brands have already taken a share of a very juicy market (growing from 1 billion in 2021 to 10 billion euros in 2026).

Some are start-ups that have brought their own vision of the market. Others are large corporations that have created a cobotics subsidiary based on their own technologies. Yet others are well-known industrial distributors that are rebranding the products of established manufacturers.

Here are the most forward-thinking actors in this quest for digital transformation in industries.

Pioneer companies in cobotics

Universal Robots

There is no company more iconic in the cobotics market than Universal Robot. Seeing the potential for lighter, flexible, and safe robots in industry, three Danish students worked on the prototype of a compact robot and founded the company in 2005.

With their first commercial model, UR5 in 2008, they were able to address the problems of SME businesses in automating redundant and tedious tasks. As they could handle many industrial applications and were easily programmable, the UR models gained momentum in many countries and sectors. With such success, they have become the market leader and have defined each evolution of the technology (safer, more versatile, and ergonomic cobots).

Universal Robot is now expanding its product lines to include stronger and more powerful cobots, improving its user interface and promoting the benefits of cobots to a wider audience.

Kuka

As a pioneer in industrial robotics, Kuka also saw the big potential of lightweight and safer robots.

As early as 1996, Kuka engineers designed a computer-controlled robot. In 2004, Kuka went one step further by buying the design of a lightweight, torque-sensing robot from the German Aerospace Center Institute. They marketed their first cobot model, the KUKA LBR 3, which worked alongside workers. Its high dexterity and precision in small free-load applications have won over a lot of companies.

As it introduced the LBR iiwaa series in 2013, Kuka generalized its flagship model with enhanced sensory capabilities and a programmable interface. Thanks to advanced features, LBR iiwaa has found its way into many industrial and non-industrial sectors.

Rethink Robotics

Rodney Brook, a pioneer in robotics, has always been skeptical of the progress of deep learning. He has especially promoted the power of human-embodied cognition as an alternative to computer intelligence. Based on this approach, he founded Rethink Robotics with Ann Whitaker in 2008 to create a human-augmenting robot.

Their first robot, Baxter, released in 2012, made a strong impression with safe gestures and a human-like interface. With their more compact and intelligent model, Sawyer, in 2015, they sought to expand their market even further.

Unfortunately, Rethink Robotics failed to convince industrial distributors and had to be sold to the German HAHN Group. Since then the company has been offering an improved version of Sawyer -that could potentially boost sales!

TechMan Robot

While TechMan came late to the cobotics race, they have stood out thanks to a very innovative culture. Founded in 2016, the Quanta Computer Group division leveraged the Korean group’s optical and electronics expertise to gain a foothold in the cobotics market.

As a result, they introduced the first cobot with reliable computer vision, TM5. This cobot series can handle parts with great flexibility. It also features the latest motion and force sensors to protect workers.

In 5 years, the Techman robot series has conquered many industries and SMEs, becoming the second most popular brand of collaborative robots on the market. Techman is also collaborating with leading automation equipment supplier Omron to design co-branded models. They are looking to extend their partnership to automate Asian manufacturing plants after the Covid-19 pandemic.

ABB

Among the cobotics players, ABB ranks among the most ambitious and innovative. This international Swedish and Swiss group is specialized in energy and automation technologies. It was a pioneer in the automation market, and manufactured the first fully electrified industrial robot (ASEA IRB).

Seeing the cobotics trend slowly emerging, they wanted to conquer this new market by hitting it big. So in 2015, they launched Yumi the first 2-armed collaborative robot. Besides having agile and productive arms, ABB wanted to show that a cobot could work face-to-face with a worker without danger.

Since then, the Yumi series has seduced many manufacturing companies, as well as food and pharmaceutical companies, thanks to sensory functions and an accessible interface. But ABB has also leveraged the power of marketing to familiarize customers and consumers with cobots.

With their latest SWIFTI and GoFA models, the group has significantly expanded its range of cobots, focusing on speed and user experience. Their ambitions are strong to make their mark on many sectors and countries.

Historic robotic companies converting to cobots

Fanuc

Fanuc is one of the companies that initiated the IT revolution in industries. A pioneer in CNC machines in the 1950s, they manufactured the first CNC robots for the Japanese market in the 1970s. In the 2000s, by joining forces with General Motor, they became the world’s leading industrial robot manufacturers.

Seeing the emerging opportunities in cobotics, they launched their own cobot model in 2015, the CR-15iA. FANUC wanted to provide their customers with a safe and versatile automation tool accessible to their workers.

Based on their long experience in robotics, the CR and CRX series of cobots have gradually expanded and are known for their high reliability and ergonomics. Their big selling point lies in their compatibility with many Fanuc equipment, to handle a wide range of industrial applications. But FANUC still has a long way to go to conquer the cobotics market.

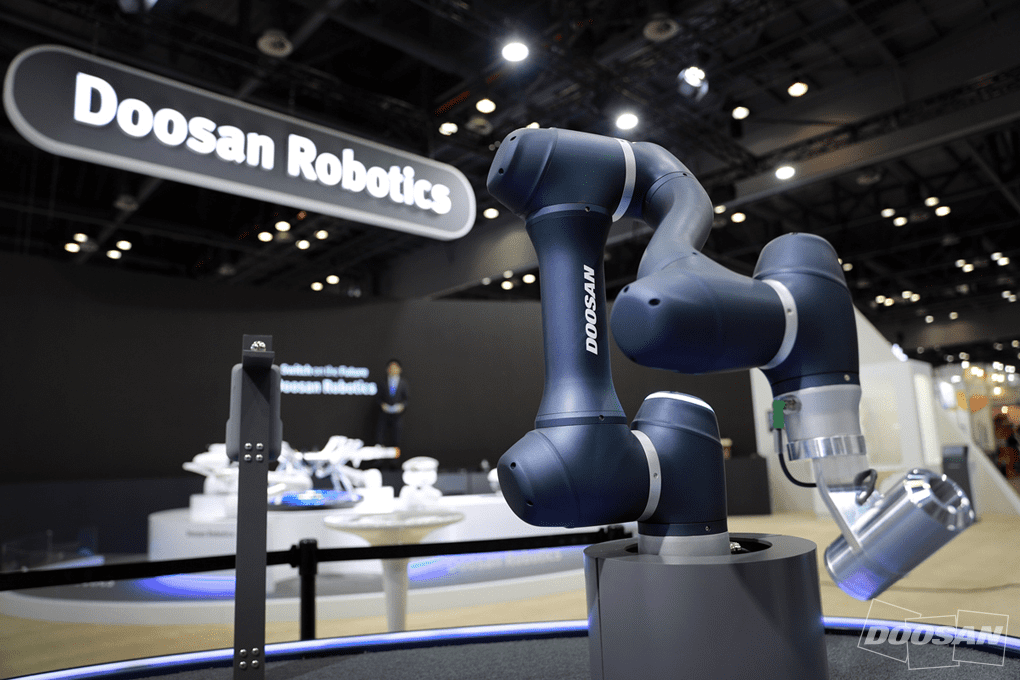

Doosan Robotic

Doosan Robotic is a subsidiary of the historical Korean group specializing in heavy industrial and construction equipment. It’s a new player in the market with ambitious plans and resources. Founded in 2016 to speed up the digital transformation of industries, the company has built a strong R&D culture to deliver outstanding cobots.

Their first models stood out for their high level of safety (with torque sensors on their 6-axis allowing advanced collision detection) and dexterity of movement. Doosan has also developed a highly praised user interface and experience.

In 2019, they launched their M series in addition to their A and H series which show very high efficiency and precision. These cobotic models show an ability to fit intense production needs. Doosan Robotics seems to have all the elements in its hands to seduce and target the large Korean and European markets.

Kawasaki

In 1960, American engineer George Devol and entrepreneur Joseph Engelberger designed the first industrial robot Unimate. Realizing the challenge at hand, Kawasaki was seduced by the idea and marketed their own version in Japan. The Kawasaki-Unimate robot defined a company culture always on the lookout for the latest automation technologies.

Realizing the extent of Japan’s demographic decline, Kawasaki Robotics worked on many cobot models in the 2010s, whether for medical treatment or food. In 2015, with duAro, the company joined cobotics with an original two-armed model. Attached to a mobile stand, it can work productively with industrial workers. Easy to program, it is capable of handling horizontal tasks with great efficiency.

In 2018, its successor, the duAro 2, gains the ability to bend its arms to handle more vertical applications. With this range, Kawasaki is trying to appeal to Asian markets for fairly broad sectors, moving from food to pharmaceutical.

Aubo

Aubo is one of the first Chinese start-ups to enter the cobotics market in the 2010s. After many years of development and research, they produced their first Aubo i5 cobot models in 2016.

Their goal has been to create robots that are versatile and scalable. The cobot components are easily disassembled and reassembled, and they can be adapted to many applications. The computer system is also open to many coding languages and accessories.

Since their first model, Aubo has greatly extended its range from Aubot i-3 to Aubot i-16. Such a series can respond to various production needs and demands. And that’s why Aubo has become very successful in China, but also in the United States.

Yaskawa-Motoman

In the 70s, the Japanese group Yaskawa built on their expertise in manufacturing electrical equipment and motors, to deliver the first electric industrial robot, the Motoman. They had great success in creating arc welding robots (which rely on electricity to melt metal). With constant technical refinements, their industrial robots pushed the limits of what was possible in terms of performance, and Yaskawa became the leader in its market in the 90s.

With its Motoman HC series in 2015, Yaskawa wanted to enter the cobotics market a little later than its competitors. Focusing on safety and hand guidance, the HCXP and HCDT models differentiate themselves by their user-friendliness. And they still have everything to prove in a very dynamic market!

Game-changer Cobotics Companies

Dobot

Founded in 2015 by Jerry Liu and his robotics classmates, Chinese company Dobot initially set out to create high-performance industrial robots. But seeing the competition in the market, they wanted to take a more innovative approach, building robots on a very small scale.

Their first small and precise model, Dobot V1, was aimed at consumers looking to automate household tasks. With much success in their Kickstarter campaign, Dobot then launched their Dobot Magician line that can do 3D printing objects, laser engraving shapes, writing, and drawing.

Originally intended for education, Dobot’s different series of cobots eventually also addressed workshops, art studios, and small industries. With their advanced sensory and ergonomic functionality, they bring a breath of fresh air to the cobotics market. And this is only the beginning!

Franka Emika

Sami Haddadin, a robotics specialist at the University of Munich, has dedicated his research to building robots that interact safely with humans. In particular, he realized the potential of universally accessible cobots to improve the lives of users, in the same way as the revolution brought about by the personal computer. He, therefore, founded Franka Emika in 2016 with this goal in mind. In 2017, he and his team presented Franka Emika Panda, a cobot remarkable for its precision and safety.

By its ease of use, it has especially seduced the world of education and research, to carry out experiments on human-machine interaction. There is no doubt that Franka Emika will bring many innovations in this field!

Elephant Robotics

While looking at existing robotic technologies, Joey Song, a Chinese student, had the idea in 2016 to design cobotics accessible to everyone. He and Wu founded Elephant Robotics with the goal of targeting not only industry-related businesses, but also those related to commerce and services.

Their first cobotic models in 2018 marked their difference with a lightweight and small size. They sought a compact design that could fit anywhere and be comfortable in any worker’s hands. In addition to being open-source and cloud-enabled, the robots offer highly intuitive controls, whether by hand or voice.

With the Catbot series in 2019, Elephant Robotics wanted to offer its innovation to industry players. With their MyCobot series in 2020, they are strengthening their product line by now targeting businesses related to services, crafts, art and commerce, and even consumers. They are also trying to target even more specialized businesses with their MyCobot Pro series.

Robotiq

In the cobotics market, innovations are not only in the design of new models, but also in the distribution and deployment of products in companies. Robotiq, for example, specializes in the creation of software and ergonomic accessories to expand the possible applications of cobots.

Robotiq offers plug & play components, which are applications that enable quick process integration and performance tracking. They also sell a wide range of end effectors, from high-end grippers, sanding kits, to all-in-one palletizing tools. They focus on accessories to facilitate the deployment of cobots and on corporate training to teach companies the benefits of automation.

A promising market for the future of cobotics!

Waypoint Robotics

WayPoint Robotics has since its inception in 2017 tackled a market that is still little considered, which is autonomous mobile robots (AMS). But unlike traditional material handling robots, their models are easily controllable, equipped with augmented sensing capabilities, and multi-directional made. This allows them to move from point A to point B while avoiding obstacles and workers.

The AMR Vector robot models are thus the allies of workers in the arduous task of transporting materials. And Waypoint Robotics is already meant to be one of the most promising and leading companies in this field !