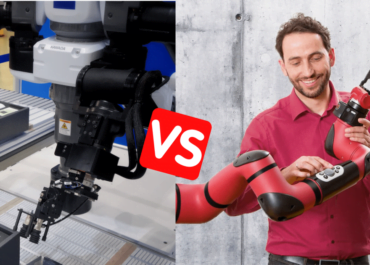

Collaborative robots are the technology that everyone is talking about. They are affordable, lightweight, and user-friendly alternatives to industrial robots.

With their lightning-fast user experience, they’re like smartphones when they took over standard cell phones.

But beyond marketing headlines, what can they concretely provide to your manufacturing company?

Here are the real benefits of automating your industrial process with collaborative robots.

The Challenges of Robotics in Manufacturing

As a plant manager, you want to leverage every opportunity to improve your manufacturing line. You want to increase your throughput, reduce your cycle time, prevent mistakes and improve your output quality.

To achieve all these goals, implementing robots has become the smart move, as it enables faster and more consistent production lines, and can get them running around the clock.

So you like many operations or production managers might have considered buying standard industrial robots like SCARA, Cartesian, or DELTA robots.

But adopting a new automation technology is not an easy task, especially for low-budget industrial companies. You might face these recurring challenges :

- High cost and investment: the initial cost of industrial robots is really high ($60000 on average) so you might not be able to attract sufficient funds or get a profitable return from them.

- Lack of Flexibility: industrial robots takes time to set them up and get them running. So they can’t adapt to part variations or production changes, and you get stuck to a permanent work configuration.

- Safety and Acceptability Issues: your workers might worry about potential hazards coming from these robots, and they might not accept them in their existing work processes (for fear of being replaced)

- Need for Technical Skills: you might not have the technical talents that can set up, program, and monitor industrial robots, or find it hard to train someone on robotic subjects.

- Lack of Data Intelligence: You might want to get real-time updates about your process efficiency, product quality, and equipment health, to make proactive adjustments.

Considering their unique features, collaborative robots have become a great way to address each of these challenges. Here’s why.

Why you should adopt a cobot for your manufacturing line

There are 5 key selling points that might make you consider adopting a collaborative robot:

#1 Affordable and Fast Return

Collaborative robots’ value for money has no equivalent. They cost an average of $20000, offer a payback time as early as 1 year, and bring significant productivity improvements. They especially make you save on labor costs and allow your employee to work on higher-value tasks.

For SMEs, cobots can be a great way to engage their first automation projects. They can leverage automation on quick-return applications with minimal investment. For example, they can automate their palletizing, machine loading, and pick-and-place processes for less than $30000.

#2 Flexibility and Quick Changeovers

Your workers might need to handle small batches of in-demand products, operate on varying parts, or change their work configuration frequently. How can you automate with the highest flexibility in these situations?

Collaborative robots can help you with that, as they are lightweight, quick to set up, and easy-to-to program. You usually need one hour to install your cobot arm or deploy it in another area. You can put it on a moving stand, to make changeovers even quicker.

Cobots’ user interface also enables you to code in no time. You can test different programs, save them, and easily switch from one to another depending on your application.

As you can see, they are an ideal solution to streamline high-mix low volume manufacturing processes. They help you implement lean manufacturing principles and adapt to unexpected changes.

#3 User-friendly and Accessibility

The shortage of talent is a common worry among manufacturers. That’s even more the case when looking for technical talents to implement new technologies.

Collaborative robots eliminate this requirement, as anyone without a technical background can set up, program, and monitor them. They provide a visual interface where users can drag and drop commands, and assemble blocks of codes. They also enable fast path demonstration via hand guiding.

Compared to the abstract and proprietary programming languages of industrial robots, it doesn’t get more straightforward than that. You just have to know how algorithm functions and how to test them. Calibrating the robot arm, connecting the various end-effectors, and debugging are also easy with guided instructions.

When it can get more complex, it’s when you want to leverage sensing technologies like vision. You need to train your sensor on different visual patterns and learn more about deep-learning software. But it’s still accessible to motivated and curious workers.

By adopting a collaborative robot, you make sure your team will be able to take the most of it. The only condition is to provide them with the right educational resources and training.

#4 Safer and Better working conditions

You know it, working in a manufacturing line every day can be physically exhausting and dangerous. That’s why taking care of your worker’s condition can only be a good thing.

Safety is especially a prominent issue, as you want to prevent any hazard and injury. The good news is, collaborative robots bring with them high-end safety technologies.

As they are ISO 10218-certified, they deliver accurate force-sensing, emergency stop, and speed limitations functions. They enable your worker to operate alongside them without worrying about harmful collisions.

Preserving your worker’ health and motivation doesn’t stop there. Implementing robots in industrial robots can often trigger resistance and fear regarding new technologies. You want them to see that these new automation tools are all to their benefit.

Fortunately, workers accept more easily collaborative robots in their work process. Their lightweight, soft and human-like design makes them look more familiar, and workers feel like they can trust them. They also know that collaborative robots are not there to replace them but to help them carry out boring and repetitive tasks like part loading, moving, and assembling. So they are more than willing to adopt them.

#5 Ever-evolving Technology

Collaborative robots are not only defined by their robotic arm. They are also part of a growing ecosystem of end-of-arm tooling, accessories, software, and a large engineer and developers community. In that sense, when buying a cobot, you’ll take advantage of ever-evolving technologies maximizing its performance and accuracy.

For example, new grippers are being built every day that enables your cobot to handle even more specialized parts. New cobot end-effectors are being designed to enable new value-adding applications like welding, sanding, or gluing. New sensors are being brought to the market, enabling you to collect more data about your manufacturing process and improve your product quality.

We have still not discovered all the automation capabilities of collaborative robots, and you still have a chance to take part in this journey!

How to benefit the most from your cobot?

Considering buying a collaborative robot? Here are three ways to make your purchase worthwhile, and make the most of it for your manufacturing line:

#1 Choose the most impactful use cases

You’ll better automate the applications that can bring the most value to your industrial processes. That way, you’ll be sure to get a profitable return, and you’ll be even more inclined to automate further in the future.

Common quick-return applications include:

- Machine-loading to continuously feed your CNC machines with parts

- Packaging and palletizing to scale your logistics applications

- Electronic assembling as cobots can handle various and sophisticated parts

- Screwdriving to speed up your final assembly processes

#2 Opt for the cobot with the best value for money

There are a lot of cobot models in the market. To choose the robot that will best fit your need and resources, here’s what to look for:

- Specs: what’s your cobot arm reach, payload, repeatability, and weight? What’s its operating speed?

- User experience: does the user interface to make it fast and easy to set up, program, and deploy your cobot?

- Safety: what are the built-in safety feature of your cobot system?

#3 Involve your workers early on

Your workers will be the primary users of your cobot, so you’ll better make them part of the decisions. What are the tasks that they despise the most, and which ones are the most painful or dangerous?

We also recommend you restructure your work organization around collaborative robots. Make it easy for your workers to check out the robot, and get back to higher-value tasks like quality control, proactive maintenance, and data analysis.

Ready to take all the benefits of cobots? Your turn to find the right automation solution for your industrial goals!