If there is one task seen as repetitive and physically demanding in factories, it’s definitely palletizing. Workers can easily get tired of moving and stacking boxes all day long.

For this reason, collaborative robots have naturally become an interesting alternative for this logistic application. As workers can easily move and reprogram them, they can manage warehouse inventories with great flexibility.

But which robotic models and effectors are best suited for this application? Here’s a comprehensive guide to opting for the automation solution adapted to your needs.

Why use cobots for your palletizing process?

Moving and storing stacks of boxes has never been the most relaxing and rewarding task. And workers know this, as they would better focus on inventory and stock management instead of filling pallets all day.

Fortunately, automation solutions have been available for the past twenty years to lighten the physical load of workers in the logistics industry, but also in the electronics and food industries. Among them, industrial robots from well-known manufacturers (Fanuc, Kuka, ABB) stack products with great productivity.

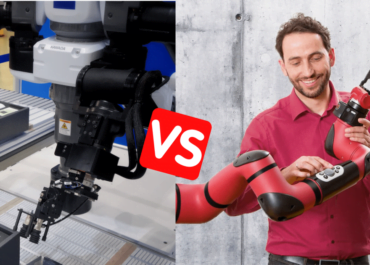

However, one of the drawbacks of these industrial robots is that they require a long time for set up, programming, and maintenance. Collaborative robots address these flaws with user experience and light-weight design while maintaining equivalent performance and redundancy.

Here’s how they can help you better automate your palletizing application:

- Easy to set up and reprogram, you can set them up within half a day on a new shop floor

- Highly consistent motion that speeds up and intensifies your conveying flow

- Lightweight and compact design to fit into your existing space and infrastructure

- They are low cost and require very little maintenance

Are these benefits appealing to you? Here’s a top of the best cobot models and palletizing tools to get you started.

Cobot for palletizing: the 5 best models

Yaskawa Motoman HC Series

Yaskawa is a company known for its industrial robots specialized in palletizing. For some years now, they’ve taken that expertise further and put it into their HC collaborative robots series, which have some of the most powerful features on the market. Here’s why you can use them in your packaging applications:

- High payload and reach capabilities to carry heavy, high-placed boxes, all without an elevator.

- Collaborative safety features, allowing them to work with workers while remaining productive.

- Equipped with an easy-to-use interface, they can be easily redeployed and reprogrammed to a new supply chain.

Doosan H Series

Since it has entered the market, industrial company Doosan has been trying to mark their difference with innovative cobot designs. With their H series, they deliver models with high load capacity and high execution speed. Like Yaskawa HC, they differentiate themselves by flawless productivity:

- They can carry boxes up to 25 kg from more than 1 meter away, all with high speed and precision.

- Their collaborative workspace features ensure both worker safety and consistent performance. You can also add to that an advanced collision detection feature.

- For their size, they demonstrate an incredibly lightweight design and can easily be moved and reprogrammed.

Universal Robot

Versatile robots by nature, UR models also perform well in packaging applications. With their higher specification models (UR10 and UR16), they can pick up large boxes with great ease and flexibility. Here are the benefits for you:

- With a wide offering, Universal Robot has a suitable model for every product size.

- They support a wide range of end effectors and software environments. They can adapt their gripping to the products you carry (food, electronics…). You can also customize the program on demand.

- Very compact and flexible, they take the space you leave them in your logistics workshops. They also have a programming interface accessible to all.

OB7 Series

A newcomer in the cobot market, Productive Robotics brings refreshing innovation to the robotic user experience. With their OB7 series, they provide robots whose main selling argument lies in their fast and easy programming features.

As OB7 robots can automatically learn from your movements, they are some of the most intuitive to teach on the market. With a 7ᵉ axis and high features, they are also very agile and productive when it comes to carrying heavy objects. Here are the reasons to invest in these models:

- A code-free programming interface, which makes installation quick and easy.

- A 7ᵉ axis and wide reach capability to reach less accessible places and objects.

- A consistency in their gesture that allows them to work 24/24 with great redundancy

Aubo I series

Chinese company, Aubo show strong assets to convince Asian factories to automate their manufacturing lines. With a wide variety of models, they work particularly well with packaging and palletizing applications. With several assets in their hand:

- A variety of technical features to handle the movement of any type of object.

- A compact, lightweight design and fast, flexible programming.

- Modularity to adapt to any effector and software system.

- The robot is easily disassembled and dismantled to speed up transportation. It is also compatible with elevators and conveyors of all kinds.

What are the best palletizing end effectors?

Schmalz

Schmalz is a leading manufacturer of vacuum pump-based automation solutions. They provide vacuum grippers for cobots and lightweight robots with reliable gripping technology for any palletizing task. With the possibility to buy components separately, Schmalz allows you to customize your solution onsite based on your product specifications. Schmalz Starters are also a complete product kit to get the right tool for your needs right away.

OnRobot

Launched last year, OnRobot’s VG20 vacuum gripper brings remarkable innovation. Running entirely on electricity, it doesn’t need any airflow and maintains a great grip on irregular surfaces and varied volumes. In particular, the VG20 can carry up to 20k of load and the user can vary the airflow to different parts of the surface.

As a result, the tool can adapt to many different types of loads with the same efficiency.

Robotiq

Well known on the market, Robotiq offers a wide range of end effectors adapted to collaborative robots. Their palletizing solution delivers a complete set-up, with mounting base, gripper and optimization software.

Their vacuum gripper compresses air efficiently, but can also operate without compressed air and has a fully customizable support. At the same time, the software allows you to adapt the air flow and robot movements depending on the size and weight of your pallets and boxes.

Piab

Piab is a large industrial group with long expertise in gripping technologies. They manufacture robotic arm tools with various installation components. With their Kenos and piCOBOT range, they deliver a compact, secure, flexible, and easy-to-change vacuum gripper kit. They are also easily customizable with the other pumps of the group.

Wadcon

Wadcon automation is a company with a long experience in automation equipment. Their Toolit offer is specifically aimed at cobots thank lightweight, clean design, and high redundancy. Whether vacuum, pneumatic or magnetic grippers, those tools can also carry relatively heavy loads. They are therefore reliable end effectors for palletizing applications.

Choosing and integrating your cobot palletizer: a step-by-step guide

When considering automating your palletizing application, choosing the ideal cobot and palletizing end effector is only one thing. The other thing is to consider more closely how to integrate this automation solution into your existing processes.

Here’s a checklist for planning your end-to-end automation project:

1. Agree on your automation project

Before you get started, think about the goals of your automation project. Do you primarily need to relieve your operators in stock management, allow them to save time on other tasks, or gain productivity in your order processes?

The answer to this question will determine what happens next.

2. Look for the right solution

Based on these goals, you can then define your preferences for cobot models or gripper tools.

There are many purchasing factors you can consider:

- Robot Load and reach capabilities based on the volume and shape of your boxes and pallets.

- The performance you expect from the robots in terms of speed, accuracy and motion redundancy.

- Gripping tool models (vacuum pump, electric, pneumatic…) according to the surface, material and shape of the objects to be moved

- The ease of programming, installation, transport and deployment of the robots

- The safety features of these robots to protect your workers

Depending on the value you place on these features, you can then select the cobot and end effector best suited to your needs.

3. Set up your logistics shop floor

Once you’ve found the right palletizing solution, you can then think about integrating it into your existing cell. This often involves reconfiguring the space and features of your warehouse or stock center.

For example, you may want to give workers or robots more room to move, or install elevators, mobile racks, or pallet suppliers.

4. Rethink the work organization

Setting up a new automation solution also means redefining the work organization and the employee contribution.

What will be the new role of logistics agents in your collaborative application? Will they be in charge of planning operations and monitoring robots? Or will they focus on transporting and handling more fragile or delicate products?

5. Conduct a risk assessment

Before deployment, you should also conduct a risk assessment of your new application. Even though collaborative robots can prevent potential collisions, you need to anticipate the points of contact, whether with the robot, the gripper, boxes, or pallets.

These different interactions can involve more complex work dynamics that your employees need to be aware of.

6. Plan employee training

Finally, you need to organize the training of your employees to this new solution. Even if these collaborative robots seem easier to use than other industrial tools, you still need to know how they work. In particular, you should insist on the safety protocols and features included with the cobot.

This will also help build employee confidence.

So now you know now how to choose and integrate your cobot palletizer into your warehouse! Do you want to have more information and details about collaborative robots? You can check out our cobot comparator.