With a streamlined production line, it’s hard to see the benefits of robot vision, apart from shiny gadgets.

When your robot is fed the right part, at the right time, and in the right place, why bother that it’s blind?

But if you want to automate a high-mix production process, robotic vision starts to feel interesting. Computer vision tools enable your robot to flexibly pick, sort and assess the quality and measurement of customized parts.

Here’s a guide on robot vision and how you can leverage it for your industrial applications.

What is robotic vision?

Let’s get straight to the facts.

Robotic vision enables robotic arms to process visual data by combining a camera with intelligence software. Thanks to 1D, 2D, 3D attached vision systems, robots can perceive and detect visual patterns, and act on them. They can for example assess a part’s quality, pick the right part in the right way, read barcodes or take measurements.

This allows for more flexibility on the production line, as robots can adapt to changing parts and automatically detect product defects.

How does robot vision work?

Robotic vision depends on two things :

A camera or other types of light sensors

They capture a visual feed and extract data from it (exposition, coordinates, color, depth values). Depending on the data, they can render 1D, 2D, or 3D images.

- 1D systems can measure the height of your object moving along a conveyor and read barcodes. They require the object to be perfectly aligned.

- 2D scanners can recognize shapes, do part identification and quality assessments on the same plane. They require constant working distance between them and the part.

- 2D,5 solutions make 3D projections from 2D images. That way, they can calculate the height and depth of objects.

- 3D technology can take more accurate measurements, as they can perceive the height, depth, and rotation of the parts. They can handle tilted, stacked objects and changing working distance.

A built-in or external machine vision software

Computer vision software process your visual data to detect patterns and act on them. They can work via rule-based or machine-learning programming.

- Rule-based vision solutions rely on predefined algorithms, so it doesn’t need a lot of training to detect your parts and can be deployed quickly on your application.

- Machine-learning vision system learns your part measurements, shape, and colors via repetitive demonstration and calibration. They enable more consistency and flexible visual detection and assessment.

What can you do with robot vision computing?

Thanks to a vision system attached to your robot, you can handle more complex and changing industrial applications :

- Barcode scanning: your robot can check parts’ barcodes to trace, identify and sort them.

- Quality control: by taking multiple pictures, your robot can detect any defect and assess your part quality.

- Measurement and counting: your robot can make sure your parts have the right specifications and that there are in the right numbers.

- Flexible part picking, assembling, and sorting: as it can differentiate shapes, your robot can pick the right parts in a high-mix feed, put them together in the right way, and sort them accordingly.

- Machine guidance: robots can easily locate the parts they are working with.

Which are the best cobot for vision?

Collaborative robots have become a must-have to handle high-mix low-volume production processes. Augmented by computer vision, they can perform even better with various and changing parts. On the cobot market, there are some models that especially stand out for their vision capabilities :

Techman Cobot

Techman is the leading brand when it comes to cobot vision. The TM cobots provide a built-in 2D or 3D camera and machine-learning-based image processing software.

With the software, you can correctly label taken pictures and train your robots on adaptable visual configurations. It’s an all-in-one solution to handle your quality inspection, measurement, and picking applications.

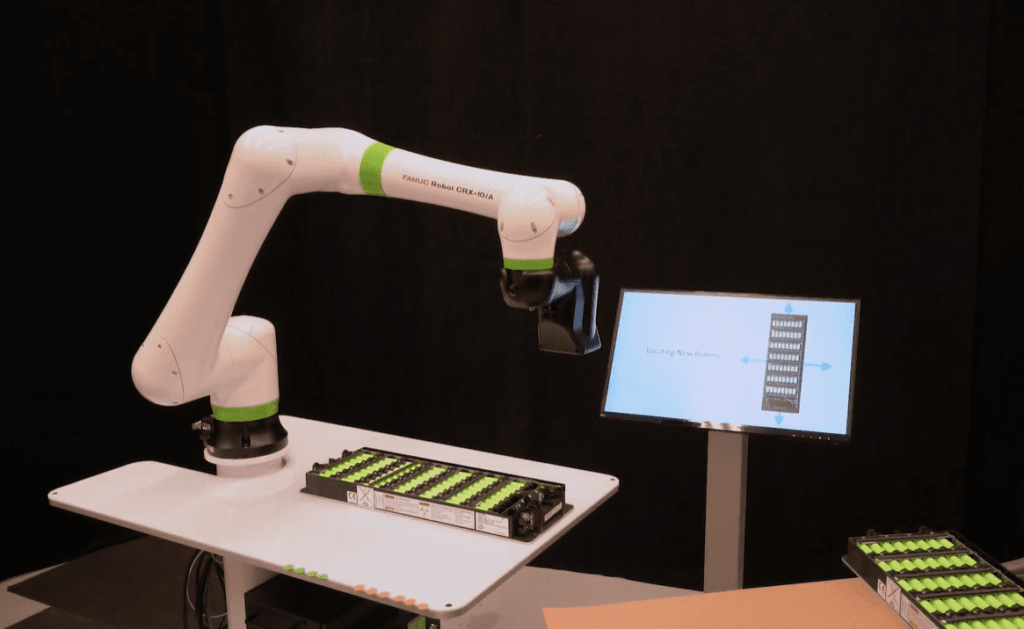

Fanuc

Fanuc CRX cobot series also features ready-to-use computer vision modules. The iRVision vision sensors seamlessly integrate into the Fanuc interface and help you quickly train your robot on a variety of images. It’s especially an easy-to-use solution for non-technical users.

Jaka

Jaka is a Chinese Company that also takes part in the robotic vision journey. Its Jaka cobots all provide plug-and-play computer vision modules. Jaka Lens 2D integrates a rule-based vision algorithm that accurately detects the brightness, noise, and axes values.

So it’s quick to calibrate and fast to deploy to your vision applications. More than that, the Jaka cobots support a wide range of third-party end-effectors and accessories.

What are the best robotic vision tools?

Historic manufacturers have long designed sophisticated vision computing solutions. Some are now providing vision effectors that can be attached to robotic arms. Here are the best providers on the market :

Cognex

Cognex is without a doubt the most innovative company in the field of machine vision. With long-standing experience building high-quality vision tools, their tools now connect to common robotic models on the market.

Their Cognex in-sight 2D robot guidance for example works with UR robot arms and helps them with part manipulation, quality inspection and data output. The tool is easy to calibrate and leverage the Cognex vision software capabilities.

But the 2D and 3D Cognex sensors also connect with other robot models (ABB, Mitsubishi, Yaskawa..).

SICK

SICK offers an easy-to-set-up vision sensor for automation-starters. Its SICK Inspector PIM60 2D provides easy integration with UR cobot and ecosystem for vision guidance applications.

The calibration is fast, and you can watch live images from the camera to adjust.

Keyence

The Keyence 2D-Vision guided robotic sensor also supports a wide range of popular robot models, so you can leverage Keyence’s industrial know-how on vision computing.

The software provides auto-calibration and robust pattern-searching technology to make the setup faster than ever. It can greatly assist your robot in picking, inspecting and positioning applications.

OnRobot

OnRobot has put on the market the first 2,5D robotic vision sensors. The OnRobot Eyes is both easy to set up and calibrate and offers depth perception for varying heights or stacked objects.

When trained, it only needs one shot to detect multiple objects and thus minimizes cycle time. It can support a wide range of robot models and can also be mounted externally.

2D or 3D robot vision: which one to choose

As I’ve mentioned before, 2D and 3D vision sensors work differently and don’t extract the same data. Depending on your needs and requirements, here’s what you can choose :

- 2D scanners are affordable and reliable options for streamlined two-axes applications. They can accurately detect, identify and assess the quality of your parts on streamlined conveyors and structured production lines. They are also easy to set up and calibrate.

- 2,5D scanners are a good in-between choice, as they are still affordable and easy to set up, but also capture more detailed visual data. It can sense the height, depth, or shades of your part to handle more unstructured production movements.

- 3D scanners perceive the shape, depth, rotation, and position of your parts on moving applications and are thus the most flexible and accurate robotic vision modules. But the technology can be quite expansive and difficult to set up.

How to deploy robotic vision in your application?

Adding visions intelligence is not a small endeavor, it involves a carefully thought-out implementation plan. Here’s a step-by-step guide to getting started on your new automation journey :

1. Identify the need for vision in your application

Which benefits are you expecting from adding vision to your application?

Do you want to improve your throughput on more high-mix production processes like picking and assembling?

Augment your part quality and consistency with inspection?

Track your parts and get overall intelligence of your production processes?

Figuring out your goals will help you with your buying decision.

2. Choose the best tool and vendor

When you know what you want, you can review existing vision solutions based on the following factors:

- The sensing technology: 2D, 2,5D, 3D, it all depends on your needs and requirements (you can check the above).

- The software accuracy and ease of use: is your software quick to calibrate, doesn’t need technical expertise to program, and can detect your parts in many different settings?

- The installation: can it be mounted on your robot or implemented externally on your production lines ?

3. Train and calibrate your robot

Now is the time to set up your vision tool for your specific application. You can rely on the robot teaching pendant or built-in vision software to program your robotic vision. There are usually two ways of proceeding :

- With rule-based programming, you just have to calibrate your tool thanks to training grids, landmarks, or plates. From these points of reference, your robot we’ll be able to rely on its predefined image processing algorithms.

- With machine-learning programming, you need to take various pictures of your part, label them accurately, and see how your robot can then process your images.

4. Rethink your work organization

Robotic vision often involves a new work organization thanks to more intelligent and flexible manufacturing processes.

So you need to reallocate your current workforce to different tasks. As your robots can handle high-mix, who will supervise them, redeploy and reprogram them when needed? Who will treat and analyze the visual and production data brought by these devices? Who will focus on more sophisticated assembly, and quality control applications?

We recommend leveraging human-machine collaboration – where robots continuously operate and workers monitor their work and are ready to intervene in any unexpected situation so that you get the best of both.

Did we help you get a clearer understanding of robotic vision applications? Now it’s your turn to augment your production line with vision!