Ever wanted to monitor the quality of your part with easy-to-set-up devices?

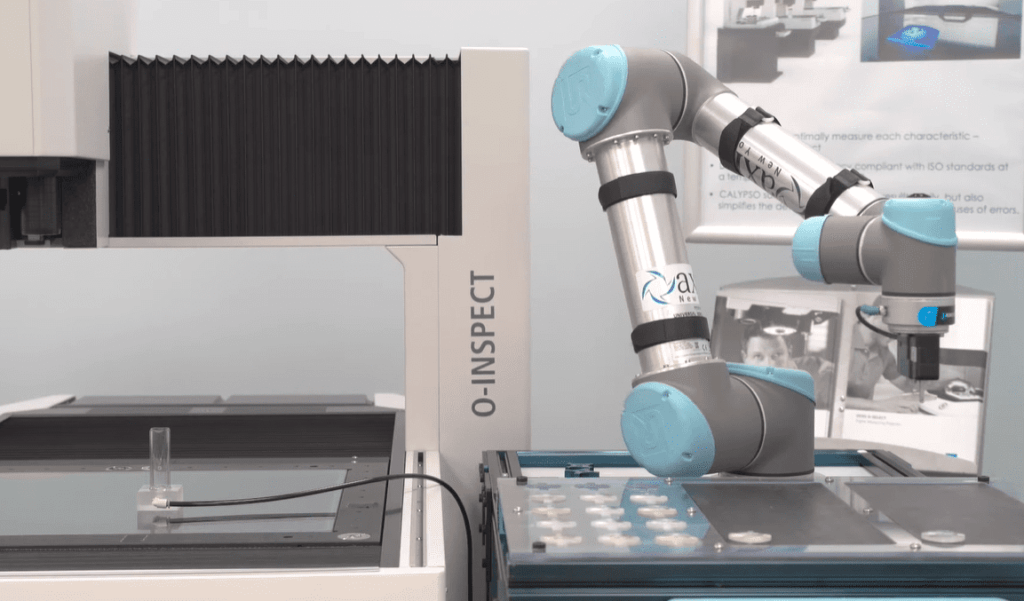

Collaborative robots have recently become a must-have in quality inspection applications. With precise vision and force sensors, they can measure product deviation, test parts, and detect defects.

But which cobot model and inspection tool to choose, and how to leverage them for your manufacturing line?

Here’s a complete guide to setting up a robotic quality control application.

Why use cobots for quality inspection and testing?

You managed to fulfill the demands of your customers in time, but realized your output quality decreased…

Quality control is a normal issue when scaling your production line. The more you increase your production capacity, the more you add complexity, and thus chance of errors.

One solution? Adding sensory technologies and data intelligence to your work processes. Collaborative robots, for example, can take consistent measurements of your parts from one work cell to another. That way you can immediately know where the defect is coming from, and how to solve it.

Compared to traditional robots or vision solutions, collaborative robots bring other seducing benefits for manufacturers :

- Accessibility: cobots are the most affordable, space-saving, and user-friendly quality control tool on the market.

- Reliability: thanks to accurate force and vision sensor, they consistently scan, test, and measure your parts, without ever damaging them.

- Flexibility: they are quick to deploy and easy to program for workers without a technical background, so they work great with changeovers.

- Safety: contrary to industrial robots, they are safe for workers to be around and actively prevent collisions.

Do you relate to that? Here’s how to get started.

Quality Control Robots: our featured list

When it comes to collaborative robot models, there are plenty of choices out there. But not of all them can provide value for quality control applications. Here are the brands of cobots that can analyze, measure, and test your parts the best :

UR

Universal Robot is a market leader with a strong offering. The UR series provides a wide range of specs to meet any of your industrial requirements, and the UR models have precise force sensing capabilities. They also connect with the most extensive partner ecosystem of end-effectors, which includes well-known quality control solutions. So you’re sure to get your money’s worth.

Techman

Techman cobots have a strong selling point: they are sold with built-in and robust computer vision. That makes them highly flexible, especially for visual inspection applications. Augmented with TM AI vision, they can be easily trained to inspect assembly, detect defects and check scratches. Moreover, the TM-series offers a complete model range for any work environment and reliable safety features.

Fanuc

Besides supporting wide options of third-party metrology systems, Fanuc also sells ready-to-use computer vision modules with its CR and CRX cobot series. The main benefit of these models is that they are easy to program and use for any operator. They also fit your existing applications and adapt to any production changes.

Jaka

Jaka is a Chinese cobot company that is delivering great value for quality control applications. JAKA cobots feature a world-class level of repeatability, at ±0.02 mm for inspection. It can also be equipped with the JAKA Lens 2D to inspect parts from multiple angles and positions. The software is fast to calibrate and deploy on a new quality management process.

Quality inspection tools for robots: our recommendations

What’s quality control without a sensing solution? To check and measure your part’s quality, you need to attach a vision or force sensor to your robot arm. Some brands on the market can provide you with reliable solutions :

OnRobot

OnRobot provides very accessible 2,5D robotic vision sensors for your quality control applications. With the OnRobot Eyes, your robot only needs one shot to scan and measure your part specs, thus minimizing cycle time. It’s also easy to set up and calibrate, and offers depth perception for varying heights or stacked objects.

OnRobot also features a 6-axis Force/Torque Sensor to allow precise handling. It can measure if an object is placed too tightly or loosely without vision capabilities.

Bruker Alicona

Long-standing expert in optical technology, Alicona also designed robust optical 3D measurement sensors for collaborative robots. DiscCobot, the TurbineCobot or the CompactCobot can deliver traceable and repeatable high-resolution measurements for specialized parts.

They can check cutting edges, parts dimensions, and surface requirements. To run them, you don’t need a technical background, thanks to automatic measurement evaluation and an easy-to-use interface.

3D Infotech

California-based company 3D Infotech has introduced metrology software for robots. The Universal Metrology system automates 3D scanning to capture dense, high-quality data for analysis in Polyworks. The user-friendly interface makes it easy to set up the system and deploy it across a variety of product families.

With this data, you can then detect and measure product deviations from 3D detailed pictures. You can even make predictive maintenance, as Polyworks alerts you about issues that may require further investigation.

Implementing quality control robots in your manufacturing line: a step-by-step approach

Integrating robot-augmented quality procedures is not that straightforward. You have to reconsider your work organization and manufacturing processes as a whole. Here’s step by step how to ensure the successful implantation of your automation solution:

#1 Think about your needs and goals

Implementing a new automation solution is all about the goals you have in mind.

Do you want to improve your output quality via consistent measurements? Do you want to get real-time data about your production processes? Do you want to ensure predictive maintenance of equipment and machines? Or do you want to free up workers from this tedious task, so they can focus on high-value work?

Starting from these different assumptions, you won’t make the same buying decision.

#2 Choose a best-fit robot and tool

When it’s time to choose the best quality control robot and sensor, you can pay attention to the following key criteria :

- Technical specs: does your cobot model feature enough reach and rotation axis to make measurements from different angles? Are they precise enough (repeatability) to scan your parts accurately? Do they fit in your existing work cell (weight and size of the robot application)?

- User experience: Are your robot and sensor easy to set up, program, and calibrate without prior technical knowledge ? Do you need to make a lot of shooting and labeling work to train the vision software?

- Flexibility: are they quick to program and redeploy on new applications, types of parts, and work configurations? Can you save and run different programs?

- Safety: does your robot provide safety features (force sensing, safe stop, collision detection..), and is your vision sensor certified?

#3 Reconsider your work organization

To leverage your new quality control system, you need to restructure your working cell. For example, you can open up the production line to let operators freely check the robot and get back to their occupations.

You also need to redefine the role of your workers. Who will supervise the robot operation, program and deploy it, check the software and data, and take corrective actions? That’s up to you to decide.

#4 Mind the Safety of your quality application

Even though collaborative robots are made to be safe alongside workers, you still need to make an extensive risk assessment of your working application.

That means assessing how your robot, sensor, parts, machines, and operators are working together. You should review any potential hazards and ways to mitigate the risks.

#5 Ensure your employees are well-trained

Your employees will be working every day with your quality control system. So they need to be the ones that know best how to manage and leverage it.

This means you need to ensure they have the educational resources and training needed to make their work more efficient. Besides, if they are familiar with this new working tool, they will better accept it in their working routine.

Do you have everything in your hands to implement a robotic quality control solution? Let’s get started!