While in the 18’s century weaving machines have automated fabric making, the manual practice of knitting makes today a strange comeback. Knitting enthusiasts, by incorporating robots in their craft, rediscover it under a more creative angle.

What we call collaborative robots (cobots) are transforming the practice of knitting, making user and robot crafting together complex weaving patterns. As Pat Treush’s experiment shows, these automation systems inspire humans new ways to practice their craft.

Here’s how the history and future of knitting show how to make human and machine collaborate.

The History of knitting automation

In its early days in 13th century Europe, the practice of hand-knitting was restricted to highly trained and experienced guild members. Knitting craftsmen followed strict guidelines gained from many years of learning.

With the arrival of mechanical weaving machines in England in the 18’s century, this practice has widespread in dedicated factories which would scale fabrics production. As the century went by, English manufacturers built mechanical systems into their production lines, which multiplied workers’ productivity by 6.

But the invention of Joseph Marie Jacquart especially revolutionized the practice of knitting complex shapes and mosaics. Jacquart’s idea was to code the weaving movements of the machine with a punch card system. Those cards divided the structure of the fabrics into x,y coordinates and replicate specific lacing techniques.

This programmable loom, which later inspired the invention of analogous computer programs, put an end to the manual practice of weaving. A simple worker could craft high quality designs and complex color shades by simply coding and testing textual programs.

But this did not mean the end of the amateur practice, especially for the women of bourgeois families of the 19th and 20th centuries. As modern societies prevented them from having a profession, women had plenty of time to knit clothes for their families. Even if their work was valuable, cultural and social constraints of the time confined their practice to traditional activity and family business. The change in societal norms since the 1960s has obviously impacted this practice passed down from mother to daughter, but it’s making a strange comeback.

In recent years, communities of weavers have emerged on social media, sharing their creations and tips for making a living. On platforms like Ravelry, practitioners see knitting as a way to express their creativity and free themselves from everyday concerns. Researches have even created a digital tool, Spyn, to capture the movements and patterns of knitters’ creations, and thus share their know-how in real time.

These new communities have tried to untangle the opposition between human and automatic knitting practices. But this difference is still present in today’s knitting practices.

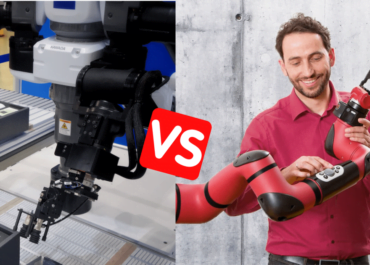

Human knitting vs weaving machine

From everywhere we look at it, human knitting practice and weaving machines process remain fundamentally different.

While the knitter’s hand operates by constant visual and tactile feedback, an automated weaving machine performs by calculation and through binary patterns.

Pat Treush and his team from Technical University Berlin, attempted to analyze the movement of hand-knitting by human hand. They placed a sensor that returns the location of the needle. The data table revealed how the needle movements were not uniform, but adapted each time to the subtle variation and resistance of the fabric. Pat would run her needle through the stitches in a rhythm that was never really constant. A knitting machine, on the other hand, looks uniform and calculated, always reproducing the same gesture very precisely.

The human variation makes therefore all the creativity of knitting. Knitters find satisfaction in bending the fabric to their will, while the resistance of the fabric pushes them to improvise. This is what makes a knitted sock or sweater never look the same, and reveals a singular knitting style.

Human knitting is here a symbolic example of any kind of human task and art, which operates by improvisation and analogical operation. Such a difference raises the question whether a robot could learn to collaborate with a human in its knitting practice. And what would be the result?

Making users and cobots knit together

Pat Teush and his team wanted to study further human-machine collaboration through the practice of knitting. They aimed to program an industrial cobot to assist the knitting of a human.

To do so, they conducted an experiment where the robot directly moves the needle and thread and assists a person in knitting. They used an industrial cobot called PANDA, which provides a software interface to guide it. Users can code in a forward-kinematics mode, where the robot’s positions and orientations are fully customizable.

For this scenario, the researchers had to find the most suitable fabric for the robot’s metal grip. They chose bamboo needles that were neither too slippery nor too stiff, and a wire thickness that was not too great. They also adapted the robot’s grip so that they could easily and accurately grasp the items. Once the robot was ready, they then taught it how to learn. The hand of an experimenter led the robot’s handle to make the right movement and to reproduce it by machine-learning. The robot had learned to manipulate a needle, moving the thread from one stitch to another.

When the robot had learned the pattern, the human knitter simply activated the execution mode and knitted in sync with its movements. While coordination was not simple at first, it was easy for the researcher to adapt to the uniform knitting rhythm of the cobot.

By sensing the robot’s haptic and tactile feedback, the human user can quickly incorporate its timing. Thus, by controlling his movement, he can perform his knitting twice as fast. This operation was even able to teach a member of the research team to sew, simply by following the robot’s instructions.

What does this example reveal about the collaboration between human and robot? That a robot can learn human practices if we adapt the conditions of its practice (equipment, timing process, …). A well-programmed cobot can complete the work of a craftsman by learning to replicate his gestures.

And this does not take anything away from the creativity and talent of the craftsman. Human knitters still need to teach to cobots new gestures and monitor their work. The role of the modern knitter is even to empathize with the robot’s haptic work, and to sense its mistakes and intentions.