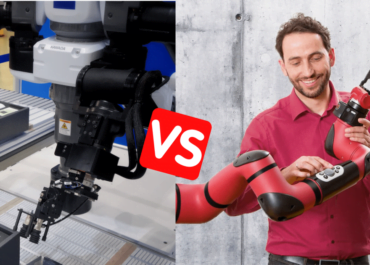

Unlike standard industrial robots, cobots operate alongside workers. This obviously implies compliance with industrial safety regulations.

But even if your cobot model is certified by recognized standards (ISO), you still need to assess the safety of their applications. Depending on your work process and the external devices involved, using cobotic products can mean added risks for your workers.

Here are the existing norms around cobot safety, and how to perform a full assessment of your cobotic applications to protect your employees and your company.

What are the safety standards for collaborative robots?

ISO 10218

In 2011, the ISO (international standard of standardization) established the ISO 10218-1 and ISO 10218-2 standards to regulate the manufacturing of industrial robot systems. To be certified, manufacturers have to conform their robotic systems to strict safety standards. They have to cover not only the risks of their system’s design but also of their accessories and their intended use in the work cell. And most cobot manufacturers (Universal Robot, Techman Robot, Fanuc, Kuka…) already comply with these standards.

ISO/TS 15066

ISO/TS 15066 is a technical specification added in 2016 to ISO 10218-1 and ISO 10218-2 to specify the case of collaborative robots. It explains 4 features that collaborative robots must have to certify as collaborative applications (described just below). Eventually, it may become a full-fledged standard, but for now, it acts only as a clarification.

So if the cobots you buy provide ISO 10218 certification, you have a certified safe robotic system for your work process. But you are still legally entitled to perform a safety assessment of your application for this product.

Which safety features do cobots provide?

According to ISO 10218, certified collaborative robots must provide at least one of 4 safe collaborative applications. Here is how they are defined in existing cobot models:

Safe stop

This application stops when it detects the presence of users in its workspace. Whether through a smart vision feature, a laser scanner, or an emergency button, it is designed to stop the cobot’s operation before any collision.

In existing models, this can take many forms. Most of them provide an emergency button on the control interface to stop any ongoing process. Others use sensory sensors to stop the process in case of a collision.

Manual Guidance Operation

One of the most common applications involves hand-guiding features. It enables work to move the cobot and teach it. Since workers use their strength, the interaction is obviously safe for the worker.

Cobot models typically use force sensors to detect the pressure exerted by workers. Free motion mode also enables easy and safe interaction for users. With this mode, they can move freely the arm of cobots along different axes.

Speed and separation tracking

Cobots can also have space-delimitation features. Users can define different zones where cobots should adapt their speed according to risk level. For example, when workers are close, the robot should slow down. When the worker is at a reasonable distance, it can speed up and operate at a maximal speed. As a result, the cobot can optimize its productivity, while still allowing proximity to humans.

In current models, the user can for example define a default work zone that cobots cannot step without stopping. They can also define collaboration zones where the cobot adapts its process to the human presence.

Power and force limitation

By design, cobots can also detect irregularities when using their force. Based on their sensor’s feedback, they can calculate the difference between the force created and the force actually required. This allows them to react in real-time to a collision by braking or reversing the movement.

Existing models have force and torque sensors to stop unwanted interaction. Collision detection technologies go a step further by preventing collisions in advance. Generally, the cobot’s lightweight and low-speed specifications also significantly reduce the risk.

Risk assessment for cobotic application: how to write it?

When you implement a cobot in your work process, you are legally responsible for assessing the risk of its use for your employees. Even if your robotic system is certified, you still need to assess the whole robotic cell, including the robotic system, its environment, and external tools.

According to ISO 10218, you must write a risk assessment document for your robotic systems following the ISO standards. Although the ISO/TS 15066 specifications are not yet recognized as a full-fledged standard, you might also already conform your document to them.

To ensure liability, this document should mention 5 chapters :

1. The identification of the document

The first chapter of your document must certify the validity, date, and author of the document. You must indicate the name of your project, its current version, and revisions, the date of publication, and the author(s) of this document. Your signature makes you responsible for the information you write in it.

2. The Project Description

This part describes in a general way why and how you intend to set up the robotic cell and the related work process. You have to explain the motivation of your automation project, the application you want to operate and the stakeholders involved.

3. Details of the machines

You have to describe the specifications and details of the systems you’re using. You might give the references of all the cobot models and accessories you use (manufacturer’s name, serial number, date of manufacture).

4. Risk assessment

Now that you have detailed the machines, you need to assess the risks involved in using them. In a table, you can use Pilz Hazard Rating to numerically evaluate the risks for each of your applications. You need to combine 4 factors to get an overall risk figure (PHR):

- Degree of possible harm

- Possibility of a hazardous event occurring

- Possibility of avoidance

- Frequency of exposure

You can then compare this result with the table provided here.

5. The risk-reducing methods

You then need to classify your risks from the most serious to the least serious. For each of them, you need to indicate ways to reduce hazards in order of priority. . In each case, you should explain how you intend to apply these methods and their limitations.

With all this, you are then ready to deploy your new robotic system. You ensure it is safe for your employees and your company!