What’s the story behind Jaka cobots?

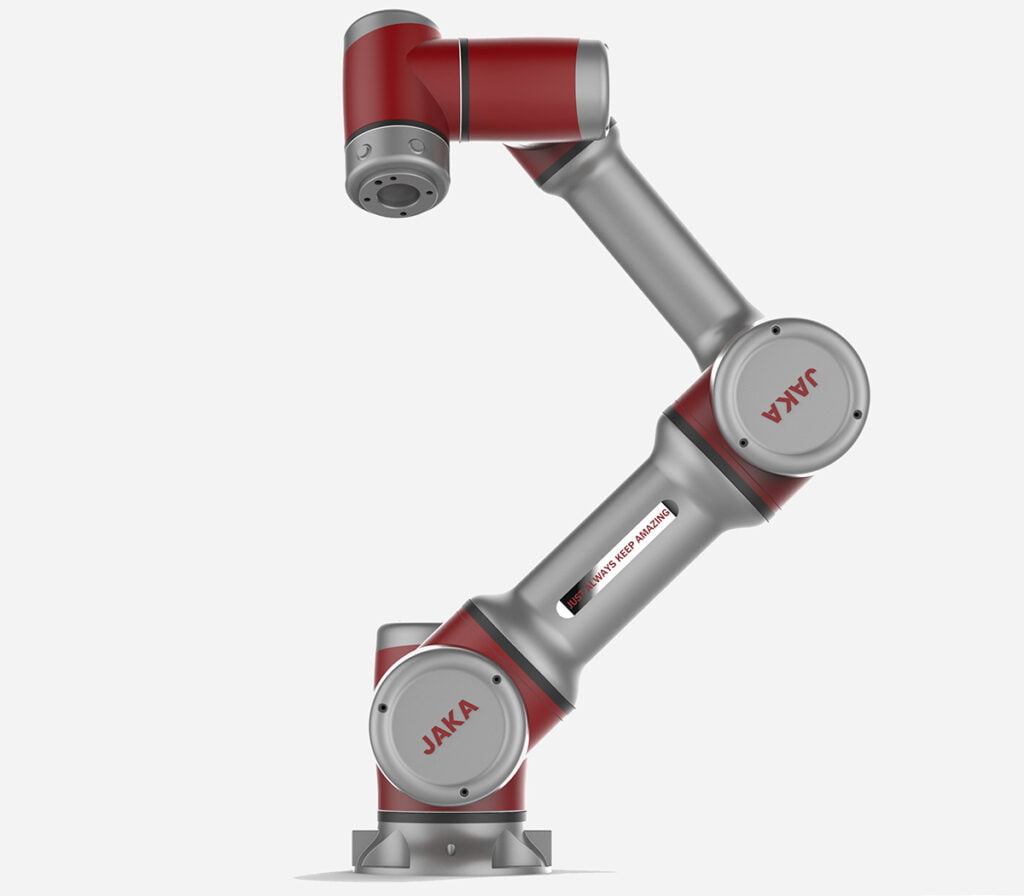

Founded in 2016, Jaka is a Chinese cobotics company that is closely collaborating with Shanghai University. With high technological know-how, they seek to become the leader in the very dynamic Asian market. Initially known more in the food and machining sector, they now want to conquer electronics and computer manufacturing plants.

To speed up their adoption in Chinese factories, they have put forward remote control and monitoring features that cross borders and distances.

With the Jaka Zu series, Jaka wants to bring a user experience that enables real-time programming from anywhere. With intense competition, how do the Jaka Zu models manage to seize their share of the Asian market?

How to use the Jaka cobot models?

After setting up the robot arm on the mounting stand and plugging the control base to the power supply, you can turn on the robot thanks to the APP control interface. On this interface, you can log in to the robot’s IP address and start the cobot before settings the safety functions (payload and installation). You then access the programmer’s dashboard where you can code your first application.

You can then drag and drop already predefined task blocks, such as linear, joint, arc, or pallet points movements. You can add your end effectors’ input/output, waiting commands, and advanced programming functions (if, then, repeat and calculation variables). In the advanced functions, you can also set up your computer vision modules, and make them detect parts.

To add working points, you can define them in the manual programming menu. Here you can use 3D modeling to control your robot remotely according to the axes and coordinates of your choice. You can provide exact coordinates or move the arm manually with the command tool. This allows you to add your new waypoints to the programming interface.

When you’re finished with your program, you can save it and run it at any given speed.

What are the main applications of Jaka robots?

With their great flexibility, Jaka Zu robots can perform many omnidirectional applications:

- Electronic parts assembly

- Screwing

- Painting and glue dispensing

- Packaging and palletizing

- Welding

- Pick & place

What to say about Jaka cobot experience?

The Jaka Zu series demonstrates great flexibility for dynamic and specialized industries. There are three main reasons for this.

First, you can easily control Jaka cobots remotely due to high-end telecommunication. Users can log into the control application from anywhere and guide the robot arm’s movements. Thanks to 3D modeling, you can visualize the robot’s tasks, and monitor the production line processes.

Second, Jaka Zu robots feature the latest robotics technologies. With Chinese technological know-how, they have ready-to-use plug-and-play vision modules (Jaka Lens Vision) that enable remote monitoring. The manufacturing quality is also good and enables easy effector integration. The Jaka Zu series provides fairly large payload and reach specifications to fit numerous applications.

Finally, you can easily get the hang of the cobot coding process. The drag-and-drop programming interface is intuitive, the manual mode makes it easy to add waypoints, and advanced logic features enable more complex applications. But do note that workers need prior programming experience.

What to make of Jaka Zu cobots ?

Overall

-

Performance

-

Usabillity

-

Safety

-

Versatility

Our Ratings

With remote control features and high flexibility, the Jaka Zu series well fits the needs of medium-sized specialized industries. It also provides a smooth and intuitive user experience that allows you to automate more sophisticated applications and keep control of your production line. The only downsides are hardly differentiating performances and less advanced safety features.