In the midst of a production line redesign, you want to set up a new automation solution to upgrade your manufacturing process?

Cobots are indeed a good way to make your industrial applications more flexible and productive, while saving space for employees’ work.

But it is not necessarily easy to choose the most suitable cobotic solution for your project. There are many models available, and they may not fit the space and resources you have available.

Here is a step-by-step checklist to guide you on the cobot buying process.

1# Define your automation needs

The reasons for your project

To start your automation project, you need first to agree on your production needs. There are several reasons to look for automation:

- Facing a shortage of manpower or high turnover

- Saving costs in high-mix, low-volume, and made-to-order manufacturing

- Improving employee working conditions in repetitive tasks

- Save space in your work environments

- Make your production lines more productive and flexible (with around the clock work).

Your objectives

In all these cases, you won’t achieve the same goal with cobotic systems. So you need to consider whether you want a cobot that is :

- Productive and efficient

- Flexible and versatile

- Ergonomic and safe

- Compact and transportable

- Intelligent and collaborative

Obviously, you can look for a cobotic model that can fulfill several of these objectives. But it helps to clarify and refine your automation need.

Applications to automate

In addition to that, you need to consider the types of applications you want to automate. Depending on their sensitivity and characteristics, cobots will not be able to handle each production process with the same ease. Here’s a list of the cobot possible applications, from the least specialized to the most specialized:

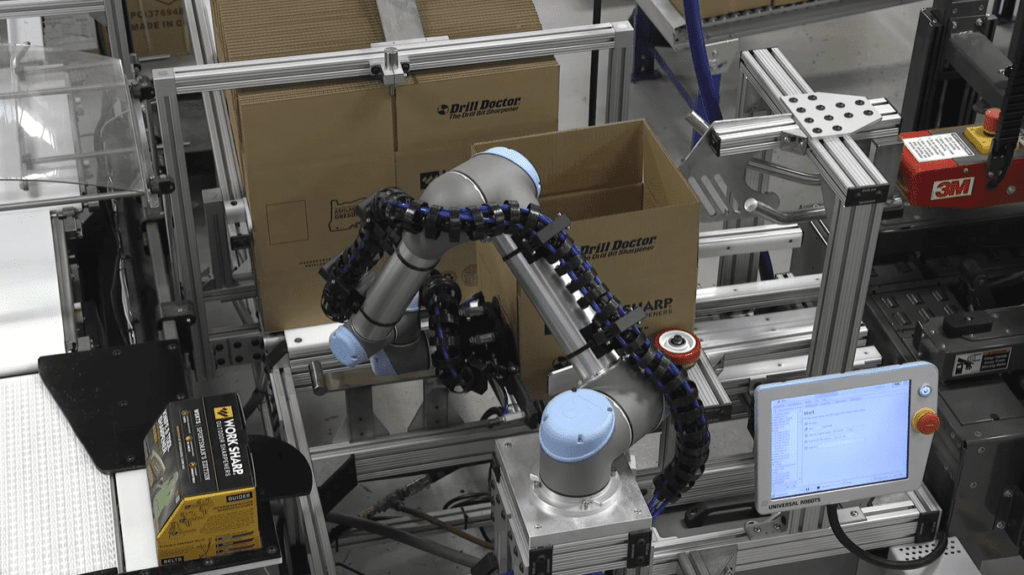

- Pick & Place

- Loading and unloading of machines

- Packaging and palletizing

- Assembly of parts

- Material distribution (painting, gluing…)

- Welding

- Testing and quality control

- Finishing (sanding, polishing…)

Depending on these applications, you will need additional features and accessories to get the job done.

2# Assess your resources

Your automation project will also not be the same, depending on the resources you have and the dimensions of your applications. You need to ask yourself specific questions about your project requirements:

- What is the budget for your automation project?

- How much time do you give yourself to set up your robotic system?

- How much space do you have for cobots in your production facilities?

- What are your available human resources, and what is their existing technical expertise?

This last point is very important since it implies defining how your cobots will fit into your existing work processes. Which training will your workers need to adopt these systems? What are the safety conditions that are required to protect workers?

According to these requirements, there are different collaborative systems defined by ISO 10218:

- Space limiting features: a cobot that adapts its pace when a worker reach its workspace. In this case, the worker can easily work next to the robot.

- Force and power regulation: these cobots are able to work next to workers in small applications without risk of injury. You can thus use them in tighter spaces.

- Hand guided operation: the cobot is easily programmable and can be quickly redeployed to different applications. It therefore aims to work in close interaction with workers.

- Emergency stop: these are cobots that stop when they perceive a danger and resume their work when the danger disappears. They can generally work in full autonomy.

Existing cobots more or less mix these functionalities, but this can help you figure out a new collaboration setting.

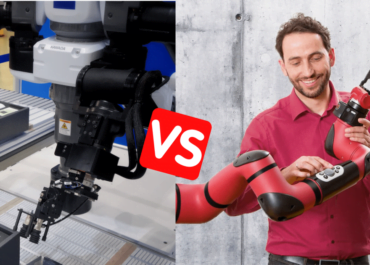

3# Review the existing cobotic solutions

Since the 2010s, the number of collaborative robot models has literally exploded. Various companies and brands of cobotics have emerged on the market and each brought innovative design. To plan your research, here’s what you can do:

- Learn about the most well-known and reliable models. You can look at Universal Robot, Fanuc, Kuka, ABB, Doosan, TechMan… to find solutions that fit your needs

- Ask these manufacturers about their features and benefits

- Compare these different robotic systems. You can also rely on our cobot reviews.

4# Compare features and prices

To achieve deeper comparison, you should focus on 5 primary factors:

Technical features

Cobots have various reach, accuracy, weight, load and speed capabilities. You should pay particular attention to reach and load to make heavy part applications possible. Accuracy (repeatability, but also fineness of the load cell) also allows cobots to handle smaller and more complex parts. If you want to focus on performance, speed and weight are critical.

Tools

Depending on the application, you will need different end effectors to plug on your cobot. These end effectors include grippers, suction cups, screwing, gluing, painting, welding, etc. In addition, there are 2D or 3D vision functions to handle more flexible applications (pick & place and quality control). Some tools can also be more modular than others, to adjust to the size of your parts.

Collaboration and safety features

As previously mentioned, the collaborative functions are not the same depending on the model. Some models have a hand guidance, a collaborative space feature…

In the same way, safety is not ensured in the same way. Torque and force sensors are more or less accurate, models can have either workspace delimitation functions or even a more advanced collision detection.

User interface

Cobot manufacturers have made great strides in improving the user experience of their cobots since the first models. Now, a touch interface, which allows for visual coding of tasks and remote control of the robot, is almost a must-have feature.

But the interfaces are more or less intuitive, and not all of them can handle more complex applications – such as those related to computer vision.

Prices

Generally speaking, prices range from 10,000 to 50,000 euros, which is much less expensive than for conventional industrial robots.

However, these prices can vary greatly from one manufacturer to another. Less established manufacturers generally try to bring more innovative and cheaper models to disrupt the market (Franka Emika, Aubo, Productive Robotics…). Find out more about them.

Otherwise, rest assured that more expensive models from recognized brands (Kuka, Fanuc, UR…) also mean better manufacturing quality.

5# Find the best supplier or distributor

Now that you know which model of cobot to buy, you need to find the right supplier to negotiate the price and installation of the equipment. In the cobotics industry, there are 3 types of suppliers that can help you:

The original manufacturer

The most reliable solution. If the company is well established, it will provide you with all the services (training, after-sales service, warranty) you will need. You get also by default the manufacturer’s warranty. On the other hand, you won’t necessarily be able to negotiate the price.

An industrial distributor

On the market, there are many historical industrial distributors who have rebranded a manufacturer’s models to reach new markets. This is the case of Omron, for example, which has taken over the TechMan robots.

With these big companies, you can be sure that you are dealing with a reliable authority and long-standing expertise.

Official cobot distributors

Many companies are expanding the distribution of manufacturers’ cobots. They usually act as consultants who analyze and adapt to your needs. You can turn to them if you are unsure of your choice or need guidance in your purchasing process. They are also often local distributors, so you can reach them nearby.

With this checklist, you can now find the perfect automation solution for your production facilities!