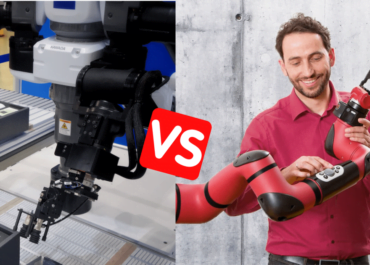

Like us, cobots need a hand to handle parts. So grippers have become a necessary tool to pick, move and release objects.

By attaching them to your robotic arm, you can automate your packing, machine loading, and bin-picking applications.

But it’s not easy to find the best gripper to hold your parts when their size, shape, and weight can vary.

Here’s a guide to help you make the right gripper buying decision.

What should you look for in a cobot gripper?

When it comes to cobot grippers, there are plenty of choices out there. Robot manufacturers have developed innovative end-effectors that can grasp different types of parts and match specific applications.

To make the best buying decision, you first need to figure out your industrial needs :

Which application do you want to automate (machine-tending, packaging, palletizing, pick-and-place, bin picking…)?

What kind of parts do you want to operate (metal parts, boxes, furniture parts, light packages, or even foodstuff ?)

Which kind of cobot do you use? What are your existing work configuration and safety procedures?

When you have all of that in mind, you can then compare and assess the grippers on the market depending on their specs and features. You can rely on these factors to make your choice :

- Specs of your part: your gripper might not hold your parts the same way, depending on their size, shape, weight, and coherence. For example, a vacuum gripper will effectively handle boxes but will struggle to grasp metal parts.

- Cobot model: your cobot models might not support every gripper model out there. Brands like Universal Robot, Fanuc, or TechMan are compatible with a wider range of end-tooling. They are also leveraging an existing ecosystem of accessories and tools.

- Gripper system: is it easy to set up on your robot arm, is it reliable, and does it work in different operating environments (hot, cold, or wet)? Does it provide built-in programming software?

- Safety: is your gripper model certified, and does your robot arm’s safety feature work with it?

What are the Different Types of Grippers?

Apart from standard finger grippers, there are many types of cobot grippers that have been developed by industrial brands. Let’s see the type of gripper that can best fit your application:

Finger Grippers

Finger grippers are the standard mechanical gripper that we naturally think of. They are electric or pneumatic-driven end-effectors that feature 2, 3, or even 4 fingers to firmly grasp your part. Thanks to opposite fingers, they can hold various parts and shapes.

More specifically, two-finger grippers can handle regularly-shaped parts. Three and four-finger grippers better hold round, spherical, or irregularly-shaped objects. So they are quite a universal solution for your industrial applications.

The main manufacturers of this equipment are OnRobot, Robotiq, WeissRobotics, Festo, Piab.

Vacuum Grippers

Vacuum grippers rely on air pressure to suck and catch objects. They are equipped with suction cups to trap air and stick to the parts thanks to the difference in pressure. That way, they can handle delicate materials and fabrics while having great lifting power.

Vacuum grippers are usually a good fit for palletizing and packaging applications, as they can handle heavy objects in a streamlined way. By enlarging or reducing the suction cup area, they can grasp a wide range of objects: Plastic parts, glass, metal sheets, cardboard packaging, or wooden pallets.

The most common brands of vacuum grippers are OnRobot, Robotiq, Schmalz, Destaco, Coval.

Soft Grippers

These gripping tools are known for their delicate touch. They are made of silicon or plastic molded materials to pick breakable and sensitive items. You can also switch from one cup to another to adapt to any part shape or size.

Due to their sensitivity and flexibility, they are particularly popular in the food, beverage, cosmetic, and pharmaceutical industries. They are used in applications such as lab testing, drug sorting, food processing, and packaging.

You can find soft grippers among companies like OnRobot, Emi Corp, SoftRobotics, SoftGripping, Ubiros.

Magnetic Grippers

Magnetic grippers are the perfect solution for unusually shaped or irregular metal parts. They can firmly pick and hold parts that are perforated or hard to grasp. Plus, they run without any air or power supply, so you’re always sure your parts are in good hands.

For these reasons, there are a must-haves in machine tending or electronic assembly applications.

The main manufacturers of Magnetic Grippers are EMI, OnRobot, Schmalz, SMC.

Gecko Grippers

New on the market, Gecko grippers are based on innovative adhesive technology to handle small-footprint objects. They are inspired by gecko skin which naturally conforms to smooth surfaces. In that sense, they can pick flat and porous objects without mark gripping or cleaning required.

Gecko grippers are cost-effective and reliable solutions to operate perforated electronic components, metallic screw heads, or other drilled materials. They thus manage specialized material handling very well.

OnRobot and Schunk are famous for selling these adhesive grippers.

Best Gripper Manufacturers: our curated list

There are some gripper manufacturers that have gained huge recognition on the market. Here’s a list of the top brands that you need to check out when choosing your cobot gripper :

OnRobot

Leader in the market, OnRobot provides a wide range of collaborative gripping products. RG 2-finger gripper can firmly grab parts from any rotation bracket, has customizable fingertips, and features augmented sensing capabilities.

FG15 3-finger gripper can handle many non-standard shapes like cylindrical objects. VG-series electrically driven vacuum grippers don’t need any air supply and are customizable to fit different sizes, shapes, and payloads. OnRobot also provides industry-proven magnetic, soft, and gecko grippers. They will help your robot manage more specialized parts and environments.

Robotiq

Another famous brand, Robotiq provides a complete range of high-end grippers.

2F-85 and 2F-140 Grippers offer plug-and-play designs, customizable wide strokes, and reliable gripping mechanisms. Hand-E Gripper holds parts with high accuracy and high payload for heavy applications.

The 3-finger gripper can pick any shape and form securely. Robotiq vacuum grippers support many handling options, are quick to set up, and can run without an air supply.

Robotiq has everything to get started in your cobotics journey.

Schmalz

Schmalz also sells plug-and-play vacuum grippers for various applications. Pneumatically or electrically driven, they are easy to set up, modular, and compatible with numerous cobot models. You can customize the number of suction cells, up to 16, and adapt to many payloads.

Schmalz grippers perform very well in palletizing, machine-loading, pick-and-place, and quality testing operations.

Piab

Piab is a large industrial group with long experience in gripping technologies. They manufacture certified, pneumatic-driven, and modular vacuum cobot grippers.

PiCobot range offers precise end-of-arm-tooling for small parts and is a great match for bin picking. Kenos range features large-area vacuum systems perfect for palletizing and packaging applications.

Both deliver space-saving, secure, flexible, and easy-to-change vacuum gripper kits. They are also customizable with the other pumps of the group.

Schunk

Schunk builds and markets robust gripping solutions. Its 2-finger Co-act gripper is one of the most reliable gripping solutions for collaborative applications. It is fully certified, has a reliable conception, and handles parts with flexible force. It is available in any variant to fit your precise industrial requirement.

EMI Corp

EMI Corp has maintained an extensive partnership with OnRobot, but also provides its in-house range of pneumatic, electric and magnetic grippers.

Its electric and pneumatic-driven finger grippers demonstrate outstanding repeatability and firm hold to your parts. They are quick to set up and connect to your I/O robot interface. The Magnetic Gripper Kit handles very well ferromagnetic parts.

Each of these grippers can be mounted on EMI tool changers, to make operational changeovers even faster.

Which Price can you expect for a cobot gripper?

You can expect different pricing depending on the type of gripper. Here’s an average cost estimate based on the offers on the market :

- Finger Gripper: 2-finger $1k-10k; 3-finger $5k-20k

- Vacuum Gripper: $2-5k depending on the number of cups

- Soft Gripper: $1-20k depending on the number of fingers

- Magnetic Gripper: $0-1k depending on the component quality

- Gecko Gripper: $500-5k depending on the surface dimension

How to integrate your gripper into your existing application: a step-by-step guide

Adding a new gripper to your robotic applications should be a well though-out process. Here’s what you need to keep in mind:

#1 Choose the gripper that best fit your requirements

As said previously, you need to figure out your industrial needs and requirements. Which applications are you looking to automate? Do you aim to speed up your existing processes, adapt to new part requirements, or improve your operational safety and reliability?

From these questions, you can then weigh up all grippers on the market and make your most-preferred buying choice.

#2 Adapt the robotic cell and check for safety

Most Cobot models are certified for safety. But that doesn’t mean your collaborative cell is safe. You need to make a risk assessment of your whole application, which includes the interaction between your workers, robots, parts, machines, and grippers.

Some grippers can imply added risks to your workers (sharp edges and unexpected collision). So make sure to consider, assess, and prevent these potential hazards.

#3 Train your workers

Your workers are the number one users of your robotic tools. To do their job, they need to know how to set it up, program it, and change it. You might thus give them every training material and resource to make the best of their new work tool.

Ready to get a hold of your manufacturing process? Your turn to find the best gripping solution for your cobot.